Single Shaft Shredder

In the era of global resource scarcity and environmental challenges, the recycling industry has emerged as a critical pillar for sustainable development.

Among the array of recycling equipment, the single shaft shredder stands out as a versatile and high-performance machine, widely adopted across industries for its ability to transform bulky waste into reusable materials.

Working video of a metal shredder

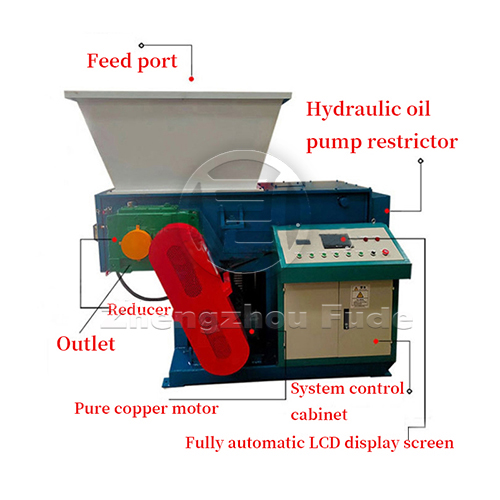

Scrap metal shredder The material enters the machine case from the feeding hopper, and the pushing box is pushed by the hydraulic cylinder to push the material towards the rotating knife roller.

The rotating and fixed knives crush the material, and the crushed material falls through the screen. It is then transported to the next process or collected and packaged through auxiliary conveying equipment.

What is a single shaft shredder machine

The single axis shredder can meet the waste recycling requirements of various industries, suitable for plastic, paper, wood, fiber, rubber, household waste recycling and treatment, and has a wide variety of recyclable materials.

Suitable for recycling various large solid materials, difficult to handle materials, plastic containers and barrels, and plastic pads. The discharge size can be reduced to 20mm according to different needs.

And we can provide various feeding hoppers according to customer needs. This device has low speed blade rotation, low noise, and is more economical.

Core Components and Innovative Design

A single shaft shredder is engineered with precision to handle complex materials efficiently. Its key components include:

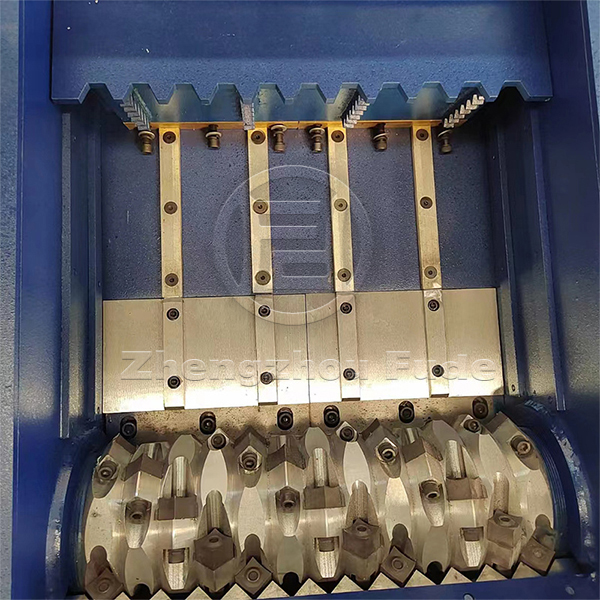

- Rotor with V-Shaped Blades: The rotor, driven by a motor, belt, and gearbox, features strategically arranged V-shaped blades that generate high shear force. These blades, made of DC53 alloy steel (hardened to HRC58-62), offer exceptional wear resistance and can be rotated 180° for extended service life.

- Adjustable Fixed Blades: Fixed blades work in tandem with the rotor blades to create a scissor-like cutting action. Their gap with the rotor blades can be fine-tuned via bolts to optimize particle size and reduce energy consumption.

- Hydraulic Push System: Equipped with a dual-speed hydraulic cylinder, the push box ensures uniform material feeding. It advances at a controlled speed to maximize shredding efficiency and retracts rapidly to minimize downtime.

- Modular Screen: The quick-release screen (available in sizes from 12mm to 100mm) determines output particle size. For enhanced safety, screens on larger models (e.g., V800) are equipped with pneumatic opening mechanisms and safety interlocks.

- Advanced Bearings and Cooling: High-strength bearings, mounted externally to prevent contamination, are paired with water-cooling systems for processing low-melting-point materials like plastics.

Single axis shredder knife roller

Single axis shredder, single machine

Single axis shredder blade

Structural diagram of single axis shredder

Product characteristics of shredder metal

- Industrial metal shredder The blade holder and blade on the rotor are detachable, making it easy to clean, maintain, and maintain;

- Each moving blade has 4 cutting edges, which can rotate 90 ° after wear and continue to be used

- Small shredder The main shaft is driven by a gear reducer, running smoothly, with low noise and high torque;

- Adopting a PLC program control system, it can automatically reverse and forward, ensuring stable machine operation

- The box is welded and tempered after welding to eliminate welding stress;

- Double shaft shredder The installation position of the moving tool is precisely processed by the machining center, ensuring that the spacing between each moving tool and the fixed tool is the same;

- Industrial metal shredder The movable knife holder is connected to the knife shaft with high-strength screws in an embedded manner, which can prevent the phenomenon of welding type knife dropping after long-term vibration

- After shredding, transportation is convenient, which can reduce transportation costs, increase transportation efficiency, and facilitate secondary processing

The working principle of a single axis shredder

Small metal shredder The thickness and quantity of shredder knives can be changed according to different materials. When crushing hollow materials, a pressing device can be equipped to increase production. The thickness of the shredder blade is divided into 15mm, 20mm, 40mm, 50mm, 75mm, and 100mm. The blade body can be selected based on the particle size of the object after crushing.

The shredding process unfolds in three stages:

- Material Loading: Waste is fed into the hopper and guided by the push box toward the rotor.

- Shearing and Tearing: As the rotor spins at 45–100 RPM, its blades engage with the fixed blades, subjecting the material to intense shear, tear, and compression forces. This multi-action mechanism ensures efficient breakdown of tough materials like rubber tires and wood pallets.

- Screening and Discharge: Shredded particles pass through the screen, while oversized fragments are re-shredded until they meet the required size. The final product is discharged via a conveyor or blower system.

The knife roller operates quickly and efficiently shreds materials

Heavy metal crusher has a wide range of applications

- Industrial waste/household waste – wood waste, kitchen waste, kitchen waste, industrial waste, factory waste, municipal sludge, fiberglass, slurry oil cloth; Biomass – branches, leaves, straw, corn cobs, wheat stalks, bark, banana trees, straw, garden waste;

- Recycled waste – waste tires, paper, plastic, plastic bottles, chemical buckets, aluminum materials;

Product document destruction – computer hard drives, document information, substandard products, expired drugs, plastic parts, - Waste treatment – medical waste, radioactive materials, organic waste, hazardous solid waste; Metal solid waste – paint barrels, paint cans, iron oil barrels, metal waste, aluminum waste.

Single shaft shredders excel in processing non-metallic and light-metallic waste across sectors:

- Plastic Recycling: They shred plastic bottles, films, and lumps into 20–50mm flakes for pelletizing. For example, the GE-S series processes 1,500–9,000 kg/h of plastic waste, reducing volume by up to 80%.

- Paper and Cardboard: In paper mills, shredders convert waste paper into 30–80mm fragments for pulping, improving fiber recovery rates by 15%.

- Wood Processing: Sawmills use shredders to produce wood chips (20–100mm) for biomass fuel or particleboard, with models like the GE-X handling 12,000 kg/h of log ends.

- Waste Management: Municipal solid waste (MSW) shredders reduce organic waste volume by 60%, facilitating composting. The GE-A series, with its swing-arm design, efficiently processes bundled textiles and films.

- Tire Recycling: Shredders break down tires into 50–100mm chips for rubberized asphalt or playground surfaces, with specialized models handling steel-belted tires without clogging.

- Electronics and E-Waste: They safely shred printed circuit boards (PCBs) and plastic casings into <20mm particles for metal extraction, meeting RoHS compliance standards.

Scrap iron

Scrap iron crushing effect

Waste cardboard box

Crushing effect of waste cardboard boxes

Used tires

Crushing effect of waste tires

Waste wood

Crushing effect of waste wood

Advantages Over Competing Technologies

Compared to dual-shaft shredders, single shaft models offer:

- Lower Energy Consumption: Operating at 30–50 kW/h for typical applications, they consume 20% less energy per ton processed.

- Higher Output Uniformity: The screen ensures 95% of particles fall within ±5mm of the target size, critical for downstream processes like extrusion.

- Ease of Maintenance: Modular design allows blade replacement in under 2 hours, minimizing downtime. For instance, the WES series features a quick-change blade system with no need for realignment.

- Cost Efficiency: Initial investment costs are 30% lower than dual-shaft alternatives, with operating costs reduced by 25% due to lower wear part consumption.

Single axis shredder for sale: Customer feedback

Scrap metal shredder for sale on site feedback photos of customers from different regions crushing different materials

Plastic bag crushing site

Scrap clothes crushing site

Tire crushing site

Foam crushing site

How to choose a industrial metal shredder machine

When it comes to the motor of the shredder, it is important to choose a guaranteed motor. Secondly, the quality of the bearings directly affects the factory power and quality of the shredder. In addition, the thickness of the steel plate must meet certain requirements.

Finally, the blade is important for the shredder. Choosing the appropriate blade will affect the later production process. The material and shape of the blade are different, and the appropriate machine model can be customized according to customer needs.

Global Trends and Future Innovations

The single shaft shredder market is projected to grow at a CAGR of 6.8% through 2030, driven by:

- Smart Manufacturing: Integration of IoT sensors for real-time monitoring of blade wear and energy use, as seen in Siemens PLC-controlled models.

- Material-Specific Customization: Manufacturers now offer hardened blades for glass-fiber-reinforced plastics and cryogenic systems for rubber crumbing.

- Circular Economy Policies: Regulations like the EU’s Waste Framework Directive are accelerating adoption in Eastern Europe and Asia-Pacific regions.

single shaft shredder for sale

Metal shredder manufacturers :The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Customized for American customers

Customized by Austrian customers

Customized for Australian customers

Customized for Canadian customers

From reducing landfill waste to enabling resource independence, single shaft shredders are redefining material recycling. Their adaptability, efficiency, and cost-effectiveness make them indispensable in the transition to a circular economy.

As industries worldwide prioritize sustainability, these machines will continue to play a pivotal role in transforming waste into wealth.

For businesses seeking to optimize their recycling operations, investing in a high-quality single shaft shredder is not just an environmental imperative—it’s a strategic advantage in the global market.

Fudemetal Crusher

Fudemetal Crusher