Metal shredder

In the era of global resource recycling and sustainable development, metal shredders have emerged as indispensable equipment in the metal recycling industry.

These powerful machines are designed to break down large and bulky metal waste into smaller, more manageable pieces, significantly enhancing the efficiency and profitability of metal recycling processes.

Operation video of scrap metal shredder

The shredder metal uses two sets of cutterheads made of high-grade alloy steel to shear each other and shred various soft and hard materials.

This machine mainly crushes and recovers ultra-thick, tough, and large materials (large pipe materials, thick wall waste).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, which has the characteristics of strong crushing ability and high efficiency.

What is a metal shredder machine?

Double axis shredder, also known as shear shredder, reduces material size through shearing, tearing, and squeezing. Its main shaft is forged solid and tempered.

The internal structure adopts a dense row moving blade structure and a hydraulic driven push plate forced feeding mechanism, which has strong crushing ability, stable performance, high efficiency, low temperature, and convenient operation.

This shredder is widely used in waste plastics, waste rubber, Drink can, iron sheet, cloth, waste paper, wood and other large volume wastes, providing reliable equipment for the crushing and volume reduction treatment of waste recycling in the early stage of our country.

Types of Metal Shredders

Metal shredders come in various types to cater to different recycling needs:

- Single-Shaft Shredders: Suitable for shredding relatively soft metals and thin-walled materials.

- Dual-Shaft Shredders: The most common type, capable of handling a wide range of metal waste, including thick-walled materials and large-sized scrap.

- Quad-Shaft Shredders: Designed for high-capacity shredding applications, offering enhanced efficiency and throughput.

Multi functional dual axis shredder

scrap metal shredder Product features

1.The blade holder and blade on the rotor are detachable, making it easy to clean, maintain, and maintain.

- Each moving blade has 4 cutting edges that can be rotated 90 ° for continued use after wear.

- The main shaft is driven by a gear reducer, running smoothly, with low noise and high torque.

- Adopting a PLC program control system, it can automatically reverse and forward, ensuring stable machine operation.

- The box is welded and tempered after welding.

- The installation position of the moving knife should be such that the gap between the moving knife and the fixed knife is the same.

- The movable blade holder is connected to the blade shaft with screws in an embedded manner, which can avoid the phenomenon of blade falling caused by welding after long-term vibration.

- After shredding, transportation is convenient, transportation costs are low, transportation efficiency is increased, and secondary processing is convenient.

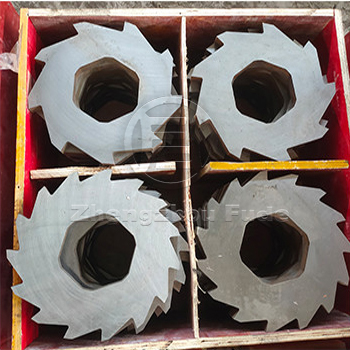

blade

coupling

Gearbox

Spacer sleeve

Advantages of Metal Shredders

- High Efficiency: Metal shredders can process large volumes of metal waste quickly and efficiently, significantly reducing processing time and labor costs.

- Versatility: These machines can shred a wide variety of metals, including ferrous and non-ferrous metals, making them suitable for diverse recycling applications.

- Environmental Benefits: By breaking down metal waste into smaller pieces, metal shredders facilitate easier sorting and recycling, reducing the environmental impact of metal disposal.

- Cost Savings: Shredded metal is easier to transport and store, reducing transportation and storage costs. Additionally, the increased bulk density of shredded metal improves the efficiency of melting and refining processes, further reducing costs.

- Safety: Metal shredders are equipped with advanced safety features, such as overload protection and emergency stop buttons, ensuring the safe operation of the machine.

Metal shredder for sale :Four reasons to choose us

- Material – Choose excellent materials based on the needs of different customers

- Process – Focusing on heat treatment process to ensure the hardness of the product

- Precision – Excellent 45 # high carbon steel casting with guaranteed hardness

- After sales – If any problems are found, we will promptly study and solve them

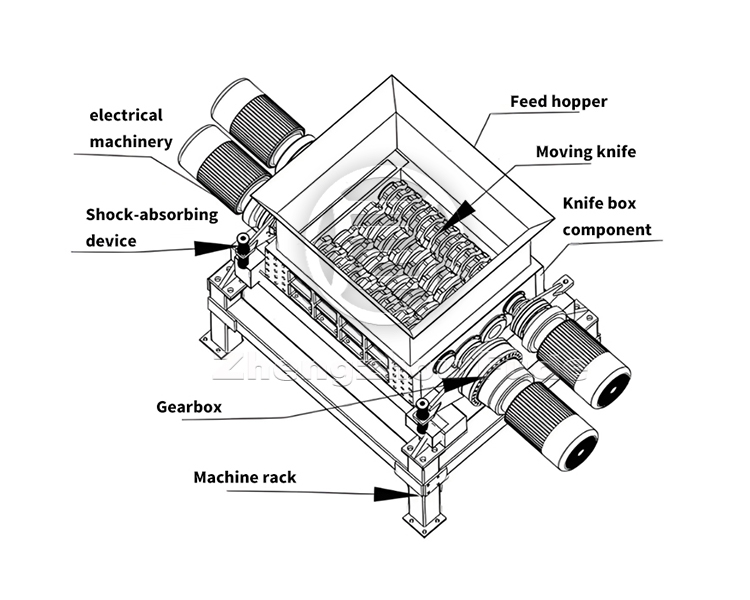

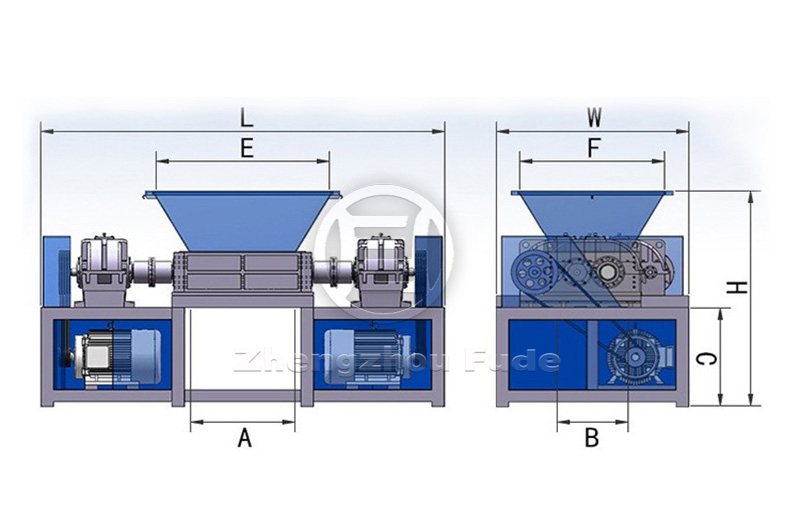

Structural diagram of the double axis shredder chassis

Dual axis shredder chassis

Key Components and Working Principle

A typical metal shredder consists of several core components:

- Shredding Blade Assembly: Comprising both fixed and rotating blades, this assembly is the heart of the shredder. The rotating blades, often designed with four replaceable cutting edges, are made from high-hardness materials like imported SKD11 steel (HRC 60° or above), ensuring durability and longevity.

- Loading Chamber: This is where the metal waste is fed into the shredder. The chamber is designed to accommodate various sizes and shapes of metal waste.

- Power System: Equipped with motors ranging from 2×11kW to 90kW, the power system provides the necessary torque and speed to shred even the toughest metals.

- Electrical Control System: This system ensures the safe and efficient operation of the shredder, featuring functions like automatic lubrication, abnormal alarm, and overload protection.

The heavy metal shredder machine relies on two relatively rotating shafts inside the machine, which are equipped with staggered blades or teeth.

After entering the machine, the material is subjected to the combined action of the blades or teeth on these rotating axes, including shear, tear, compression and other forces, and is broken into small particles or fine threads, thereby achieving the goal of reducing the size of the material.

This design is particularly suitable for handling materials with large volume, high hardness, or difficult to break, such as scrap metal, plastic, waste rubber, wood, etc.

Double axis shredder structure

Metal shredder manufacturers:Widely applicable

Metal shredder made in china,Widely used in waste plastics, tires, waste rubber, wood, paint barrels, waste home appliance shells (plastic shells, metal shells), waste circuit boards (circuit boards), waste cables, rubber, leather, ton bags, films, and other solid waste, allowing limited resources to circulate indefinitely.

Metal shredders have an extremely wide range of applications. In the automotive recycling industry, they can efficiently process scrap vehicles and their components to achieve metal recovery; in metal processing and manufacturing, they can handle scrap materials, old molds, and casting waste to promote waste reuse;

In the construction and demolition sector, they can crush construction waste and metal debris from demolition sites; in electronic waste recycling, they can dismantle appliances and electronic devices to extract precious metals and non-ferrous metals; in the packaging and logistics industry, they can recycle metal packaging containers and logistics pallets; in the energy and power sector, they can process scrap transformers and cables; in the aerospace and defense industries, they can dismantle scrap aircraft and defense waste;

In municipal and environmental engineering, it can process metal waste and metal debris from post-disaster rubble; it can also handle special metal materials such as stainless steel and alloys, and even provide raw materials for metal sculpture production and DIY crafts in the art and creative industries. Its strong adaptability, high crushing efficiency, controllable output particle size, and environmentally friendly and energy-saving technical advantages provide strong support for metal waste processing and resource recycling across various industries.

Scrap iron

DoublScrap iron crushing effect

Waste tires

Crushing effect of waste tires

Waste cardboard box

Crushing effect of waste cardboard boxes

Big Blue Bucket

The crushing effect of the large blue barrel

Fruit basket

Fruit basket crushing effect

wood

Wood crushing effect

How to choose a wood shredder

Firstly, when choosing a scrap metal shredder, it is necessary to consider the properties of the material being processed, such as size, shape, hardness, etc., to ensure that the machine can effectively crush the material.

Secondly, the amount of processing capacity is also crucial when selecting a machine, as it directly affects the work efficiency and production capacity of the machine.

The corresponding model can be selected based on the amount of processing required per hour, and the selected model can ensure that it can meet production needs through the two key factors of material and processing capacity. (Customizable models according to customer needs)

wood chipper shredder,Good customer feedback

Double shaft plastic shredder,On site feedback photos of customers from different regions crushing different materials

Türkiye Customer Crushing Old Cloth Site

Canadian customer crushing industrial plastics on-site

Austrian customer crushing large blue barrels on-site

US customer crushing wood on-site

Choosing the Right Metal Shredder

When selecting a metal shredder, consider the following factors:

- Material Type and Size: Determine the types and sizes of metal waste you need to shred to choose a machine with the appropriate capacity and blade configuration.

- Throughput Requirements: Assess your production needs to select a shredder with the right processing capacity.

- Budget: Consider your budget constraints and choose a machine that offers the best value for money.

- After-Sales Service: Opt for a manufacturer that provides comprehensive after-sales service, including installation, training, and maintenance support.

wood chipper and shredder,Delivery site

Wood pallet shredder manufacturer,The factory arranges different logistics vehicle sizes according to the customized machine models and sizes of different customers, ensuring timely delivery and reliable transportation

Customized machine shipment from Russian customers

Customized machine shipment for American customers

Malaysian customer machine shipment

In the dynamic landscape of metal recycling, the metal shredder stands as a game-changer, offering unparalleled efficiency, versatility, and environmental benefits. By investing in a high-quality metal shredder, recycling businesses can streamline their operations, increase resource recovery, and contribute to a more sustainable future.

Whether you’re a small-scale recycler or a large industrial facility, there’s a metal shredder out there that’s perfect for your needs. Embrace the power of metal shredding and unlock the full potential of metal recycling today!

Fudemetal Crusher

Fudemetal Crusher