Can Flattening Machine

Aluminum Can Flattener for Recycling and Disposal

| Name | Can crusher |

| Customization | yes |

| type | press |

| Applicable scope | Various aluminum cans, iron dew cans, beer cans, milk powder cans, etc |

In the realm of waste management and resource recycling, the aluminum can flattening machine (also known as a can crusher, can flattener, or can press) has emerged as a revolutionary tool.

Designed to compress aluminum and steel beverage cans in bulk, this equipment significantly reduces storage and transportation costs while enhancing the efficiency of recycling operations.

This article provides an in-depth look at the aluminum can flattening machine, exploring its working principles, advantages, and applications in the global recycling industry.

Working video of aluminum can flattening machine

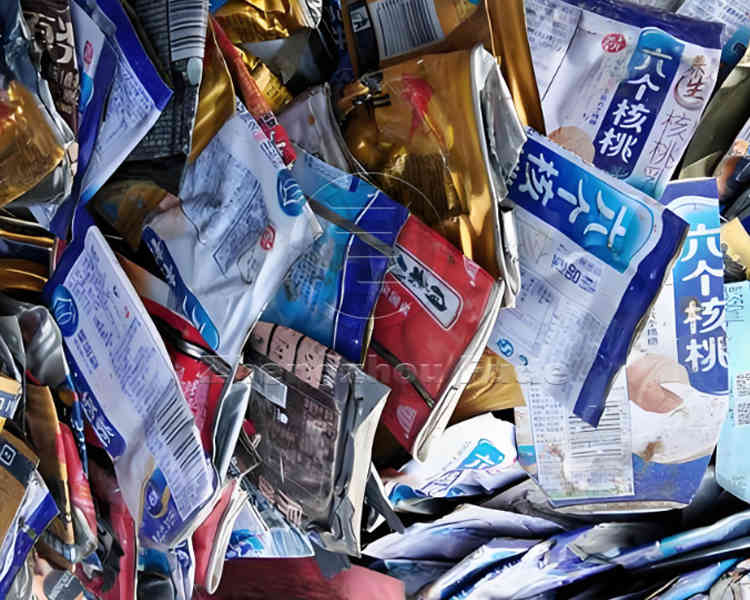

Aluminum can flattening machine is a processing equipment that flattens the body of all aluminum cans and iron cans (such as small Wangzai cans; coconut juice, coffee cans, dew cans; Wangzai milk and beverage cans; Jia Duobao cans, etc.) after removing the aluminum cap.

It reduces space occupation, facilitates transportation, and increases profits.

Why is it called an aluminum can flattener?

The purpose of the flattening machine design is to compress discarded cans and then put them into a recycling bin for storage. Two pairs (four) of rollers are used to achieve flattening work through two rounds of rolling, which can flatten and flatten cans.

Mainly used for flattening the bodies of gold aluminum cans and iron cans (such as small Wangzai cans of coconut juice, coffee cans, dew cans; Wangzai milk, red cow beverage cans; and its positive and Jiaduobao cans).

Flattening machine single machine

Flattening machine single machine

Working Principle of Aluminum Tin Can Flattening Machine

The aluminum can flattening machine operates on a straightforward yet effective mechanism. It typically consists of a motor, a reduction gearbox, and two opposing rollers.

The motor drives the rollers through the reduction gearbox, which decreases the rotational speed while increasing torque. As cans are fed into the machine via a hopper or conveyor belt, they are crushed between the two rollers, transforming from cylindrical shapes into flat, compact pieces.

Some advanced models incorporate additional features such as stepper motors and gear systems to ensure precise control over the flattening process. These machines can automatically feed cans to the crushing mechanism, enhancing automation and productivity.

Additionally, certain designs utilize a dual-roller compression process, applying pressure in two stages to prevent the cans from rebounding and ensuring a uniform flattened shape.

Flatten machine Suitable for multiple industries and widely used

The aluminum can flattening machine finds widespread use across various sectors, including:

- Recycling Centers: Efficiently processing large volumes of cans collected from households, businesses, and public events.

- Waste Management Facilities: Reducing the volume of cans in municipal solid waste streams, optimizing landfill space, and enhancing recycling rates.

- Beverage Manufacturers: Managing production waste and packaging materials, promoting sustainable manufacturing practices.

- Hospitality Industry: Hotels, restaurants, and catering services use the machine to dispose of used cans responsibly and cost-effectively.

- Retail Stores: Supermarkets and convenience stores flatten cans for easier storage and transportation to recycling facilities.

Aluminum cans

Iron can

Beer can flattening effect

Flattening effect of iron dew cans

Flattening effect of various aluminum cans

What are the advantages of aluminum can flattening machines

- Space Efficiency

One of the most significant benefits of the aluminum can flattening machine is its ability to dramatically reduce the volume of waste cans. By compressing cans into flat sheets, the machine can reduce their storage space requirements by up to 80%. This space-saving feature is particularly valuable for recycling centers, waste management facilities, and businesses that generate large quantities of aluminum and steel cans.

- Cost Reduction

Flattened cans are easier and cheaper to transport. The reduced volume translates into fewer trips required for waste collection and recycling, leading to lower fuel consumption and transportation costs. Moreover, the compacted cans occupy less space in landfills or recycling plants, further minimizing disposal expenses.

- Enhanced Recycling Efficiency

The flattened cans are more suitable for subsequent processing steps, such as shredding, melting, and remanufacturing. Their uniform shape facilitates easier sorting and handling, improving the overall efficiency of the recycling process. Additionally, the machine’s ability to process both aluminum and steel cans makes it a versatile solution for diverse recycling needs.

- Labor Savings

The aluminum can flattening machine is designed for ease of use and minimal maintenance. With automated feeding systems and simple controls, a single operator can manage large volumes of cans efficiently. This automation reduces the need for manual labor, lowering operational costs and minimizing the risk of workplace injuries.

- Environmental Benefits

By promoting the recycling of aluminum and steel cans, the machine contributes to reducing the environmental impact of waste disposal. Recycling these materials conserves natural resources, reduces energy consumption, and decreases greenhouse gas emissions associated with primary metal production.

Feedback from customers from different regions on flattening aluminum cans on-site

We consulted and followed up with customers in Canada, Germany, Thailand, and Pakistan regarding the effectiveness of using flattening machines, and they provided satisfactory responses.

German clients

Pakistani clients

Thai clients

How to choose the correct aluminum can flattening machine

Firstly, from the pressure of the aluminum can flattening machine, a higher pressure means that the machine can more effectively compress the aluminum can and improve production efficiency.

Furthermore, the production capacity of aluminum can flattening machines varies with different models, and the size of the production capacity is related to factors such as the diameter and stroke of the oil cylinder used by the machine, as well as the power of the motor.

When purchasing and using an aluminum can flattening machine, it is necessary to choose the appropriate machine model, pressure, output, etc. according to your own needs to achieve the best results.

Customized machine loading and shipping for customers in different regions

Customized machine models, sizes, styles, and other aspects vary according to the different needs of each customer

Customized by Russian customers

Customized for Australian customers

The aluminum can flattening machine is more than just a piece of equipment; it’s a symbol of progress in the recycling industry. By combining efficiency, versatility, and environmental benefits, it offers a sustainable solution for managing can waste in today’s world.

As businesses and communities continue to prioritize sustainability, the adoption of such innovative technologies will play a crucial role in building a greener, more resilient future.

Whether you’re a recycling center looking to optimize operations or a business seeking to reduce your environmental footprint, the aluminum can flattening machine is an investment worth considering. Embrace the future of recycling today and make a positive impact on the planet.

Fudemetal Crusher

Fudemetal Crusher