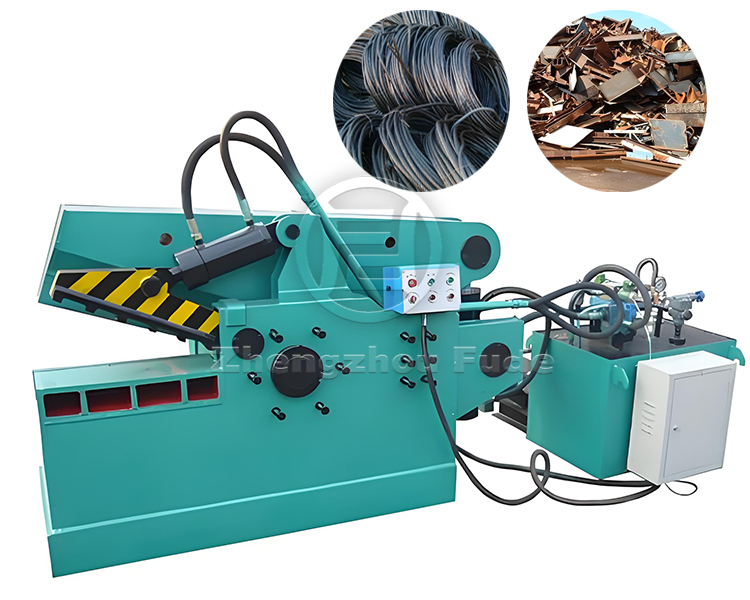

Metal crocodile shears

Metal Shears for Scrap Metal Sheet Processing and Disposal

type:Cutting machine

Applicable objects:Reinforced steel pipe and iron sheet

customized:yes

quality assurance:a year

Driving method:electrical machinery

Layout form:horizontal type

The Alligator Shear, also known as the Crocodile Shear, is a hydraulic-powered metal cutting machine designed for cold-shearing various metal profiles, including steel plates, rods, angle iron, and scrap vehicles.

Its name derives from its jaw-like structure, mimicking the powerful bite of a crocodile. Widely used in metal recycling yards, automotive dismantling sites, and steel mills, this machine combines rugged construction with precision engineering to deliver efficient, cost-effective material processing.

Motor version of the metal shear operation use

This crocodile shearing machine can be operated continuously automatically or manually in a single operation, making it a good processing equipment for cutting heavy waste, light and thin furnace materials, and steel bars.

should i crush plastic bottles for recycling

The crocodile type shearing machine is an efficient and powerful metal shearing equipment, mainly used in the recycling industry of waste materials, steel, non-ferrous metals, and other metal processing industries.

Its design inspiration comes from the mouth of crocodiles, which simulate the biting action of crocodiles to achieve cutting of metal materials.

Key Features

Hydraulic Drive System

- Powered by a hydraulic pump, the machine generates forces ranging from 63 to 400 tons, enabling it to shear through thick metal sections with minimal noise and vibration.

- Compared to mechanical systems, hydraulic drives offer smoother operation, easier maintenance, and built-in overload protection.

Adjustable Blade Length and Force

- Blade lengths span 400mm to 1,500mm, accommodating materials from rebar to large I-beams.

- Models like the Q43-1000 deliver 1,000 kN of force, cutting 600mm-wide steel plates at 6–12 strokes per minute.

Portable and Versatile Design

- Compact units (e.g., 6,500kg weight) require no fixed foundation, making them ideal for mobile recycling operations.

- Diesel-engine options allow operation in remote areas without electricity.

Safety and Durability

- Equipped with emergency stop buttons, guard fences, and automatic overload shutdown.

- Hardened steel blades resist wear, while lubrication systems ensure longevity.

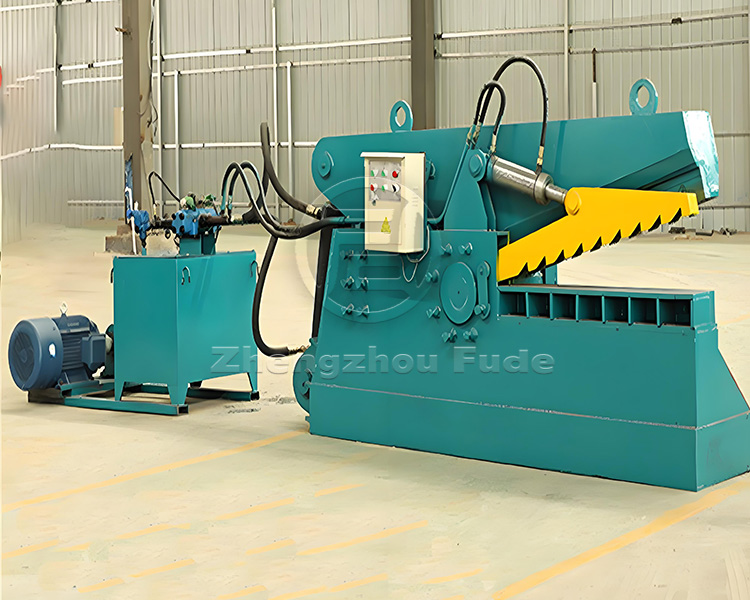

Crocodile type metal shearing machine

Cutting machine factory diagram

Steel pipe shearing machine

What is the working principle of the crocodile type shearing machine

The alligator-style shear machine achieves efficient cutting through a hydraulic drive system: the motor drives the hydraulic pump to generate high-pressure oil, which pushes the cylinder piston to move back and forth, causing the moving blade frame to close toward the fixed blade frame in an “alligator jaw opening and closing” manner.

When metal materials are fed into the blade gap, the hydraulic system continuously applies pressure, and the sharp edges of the moving and fixed blades generate immense shearing force, instantly severing the material.

Its core advantages include adjustable pressure, overload protection, and low-noise stable operation, making it an ideal cold-cutting tool for applications such as metal recycling and scrap vehicle dismantling.

hydraulic cylinder

Safety Signs

Detail drawing

Shearing knife

Scrap metal shearing machine product parameters

| model | 160T | 200T | 250T |

| Maximum shear force | 1600KN | 2000KN | 2500KN |

| Maximum pressure | 190KN | 190KN | 190KN |

| Blade length | 800MM/1000MM | 1000MM | 1000MM/1200MM |

| Maximum opening of the blade | 300MM/400MM | 400MM | 400MM/500MM |

| electrical machinery | 15KW | 18.5KW | 22KW |

| Number of cuts | 7-10 | 8-10 | 8-10 |

Shearer equipment in the metal industry

The metal shearing equipment is mainly used in the waste material processing industry, dismantling plants, small and medium-sized steel plants, metal crushing plants, etc., to perform cold shearing on various forms of metal and further process them into qualified furnace materials.

There are various advantages in the metal processing industry, such as easy operation, simple structure, high shear pressure, and low maintenance costs. It is driven by hydraulic pressure and has the characteristics of small volume, low noise, and smooth operation. It is easy to achieve overload protection and provides an efficient and convenient solution for waste material recycling and metal material processing.

Crocodile shear steel pipe shearing machine

Industry Status and Development Trends

In the scrap metal recycling industry, alligator-style shearing machines have become the industry standard. According to statistics, China processes over 200 million tons of scrap metal annually, with 70% of the processing workflow relying on shearing machines. As the “dual carbon” goals are advanced, equipment is upgrading toward intelligent and energy-efficient directions:

Fully automatic control: Integrated with a visual recognition system, it automatically identifies material types and adjusts shearing parameters.

Modular design: Core components such as blade holders and cylinders support quick replacement, reducing maintenance time by 60%.

Green manufacturing: Utilizing low-noise hydraulic valves and energy-efficient motors, energy consumption per unit of output is reduced by 15%.

Metal plate shearing machine use effect

Advantages Over Competitors

- Cost Efficiency: Lower maintenance costs than mechanical shears due to fewer moving parts.

- Precision: Adjustable blade gaps ensure clean cuts, reducing material waste.

- Mobility: Portable models enable on-site processing, saving transportation costs.

- Safety: Compliance with CE and ISO standards minimizes workplace accidents.

The Industrial metal shears has strong cutting ability, simple and convenient operation, high cutting accuracy, wide applicability, low maintenance cost, and environmental protection and energy conservation advantages in the metal processing industry. These advantages make crocodile shearing machines an indispensable and important equipment in the fields of waste material processing, dismantling, and recycling.

Metal shears for sale at favorable prices

Application scope of crocodile type shearing machine

The Metal Cutting Shears is mainly suitable for various metal waste materials, including but not limited to scrap iron, scrap steel, steel bars, steel pipes, steel plates, angle iron, channel steel, square steel, round steel, and other materials.

This equipment can perform cold shear processing on these materials, making them qualified furnace materials or other reused materials.

It is also suitable for fixed length cutting of steel profiles in steel mills. It has a wide range of applications, not only suitable for waste recycling stations, metal processing plants, metal dismantling plants, smelting and casting plants, but also suitable for places such as scrap iron recycling stations, steel mills, crushing plants, and automobile dismantling plants.

Metal Recycling

- Process scrap cars, appliances, and structural steel into furnace-ready billets.

- Example: A Q43-200 shear cuts 800mm-wide steel plates into 200mm chunks for smelting.

Automotive Dismantling

- Disassemble vehicle frames by shearing through chassis components and axles.

Steel Mill Operations

- Cut hot-rolled billets or defective products into manageable lengths for reprocessing.

Construction Waste Management

- Recycle rebar, steel beams, and mesh from demolition sites.

rebar

wirerope

Iron sheet

Tire rims

gas tank

color steel tile

steel pipe

steels

Precautions for Hydraulic Metal Shears

1.Operators: Ensure that they have received professional training and understand the equipment operation and safety regulations.

2.Lubrication and maintenance: Regularly add lubricating oil and butter to maintain the equipment in good condition.

3.Material handling: Avoid cutting prohibited materials and do not use hands to directly contact materials or moving parts of the machine.

4.Safety protection: Wear personal protective equipment and keep away from the transmission and cutting edge.

5.Start and stop: Before starting, ensure that there are no obstacles above the machine. After stopping, wait for it to come to a complete stop before operating.

6.Rainy protection: Avoid working outdoors to ensure safe and dry operation of the machine.

7.Maintenance and repair: Do not repair during work, inspect and maintain after shutdown.

8.Power management: Turn off the power when leaving the position to ensure safety.

The Alligator Shear is a cornerstone of modern metal recycling, offering unmatched power, precision, and adaptability. Whether processing scrap vehicles in Europe or structural steel in Southeast Asia, this machine delivers reliable performance while adhering to global safety standards.

For customized solutions, contact manufacturers like Fude Machinery, We specialize in customizing cutting machines according to specific industry needs.

Fudemetal Crusher

Fudemetal Crusher