Introduction and Characteristics of Can Flattening Machine

746Aluminum can flattening machine is a specialized mechanical equipment used for flattening and forming metal cans.

View detailsSearch the whole station

Plastic waste is a big problem. It piles up fast. Businesses need to handle it.

For businesses, ‘destroying plastics’ usually means processing them. This gets plastic ready for recycling. Or it makes it smaller for easier handling and disposal. It turns a waste problem into a manageable step.

Understanding this process helps businesses save money and operate better.

Plastic waste is hard to handle. It comes in many shapes and sizes. Businesses need specific ways to break it down.

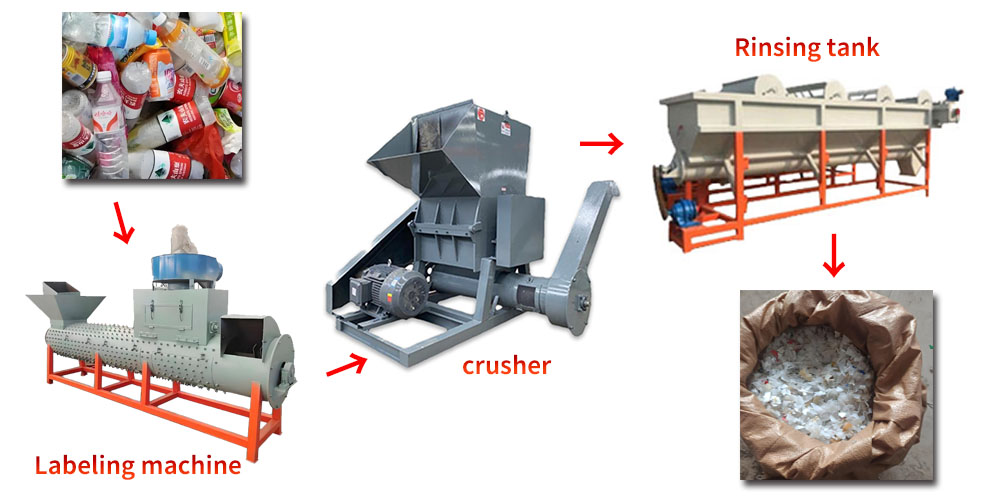

Businesses process plastic waste using machines. These machines cut and break the plastic into smaller pieces. This step is called size reduction. Shredding is a common method.

I know processing plastic needs the right steps and the right machines. It is more than just breaking it.

Collecting the Plastic

Shredding the Plastic

Sorting if Needed

Sizing Further

Moving Materials

Businesses use different setups based on their plastic. They pick steps that work best.

Handling plastic waste needs special tools. The plastic is tough. It needs strong machines to break it down.

Businesses use industrial machines to process plastics. Shredders are the main machines. They also use conveyors, sorting machines, and screens to handle the plastic stream.

I provide the machines businesses need for this work. My equipment is built to handle tough plastic materials. Here is what is used.

Some businesses just need one machine. Others need a full system. A system handles plastic from start to finish.

A plastic processing production line is a set of machines working together. It takes plastic waste as input. It outputs processed plastic ready for the next step, like recycling or disposal. It makes the process automatic.

I design and build complete production lines for plastic processing. These lines handle plastic efficiently.

Why Use a Full Line?

Customization

These full lines are powerful tools for businesses with lots of plastic waste.

Businesses need reliable machines. They need good support. They need a partner they can trust.

You should get plastic processing equipment from me because I offer complete solutions. I customize machines for your needs. I provide full service from start to finish. I offer competitive prices directly from my factory.

I build high-quality machines. I help businesses succeed with their plastic processing challenges.

Customization Ability

Factory Direct Price

Full-Service Support

Global Experience

Industry Experience

Choosing me means getting the right tools and support for your plastic processing.

Processing plastic waste is important for business. It saves money and helps the planet. I provide the machines and service you need to do it right.

Aluminum can flattening machine is a specialized mechanical equipment used for flattening and forming metal cans.

View detailsWhen selecting and using crocodile scissors, it is necessary to consider the specific production needs and actual situation comprehensively.

View detailsOverview of Shredder Scrap Prices in 2026Detailed Shredder Scrap Prices Chart (2026)Key Factors Influencing Scrap Prices1. Global Steel Production and Demand2. Energy Prices and Transportation Costs3. Environmental Policies and Carbon Taxes4. Exch...

View detailsWhat is a Metal Recycling Shredder?Factors Affecting the Cost of Metal Recycling ShreddersAverage Cost of Metal Recycling Shredders in 2026Benefits of Investing in a Metal Recycling ShredderTop Metal Recycling Shredders on the MarketFrequently Ask...

View details