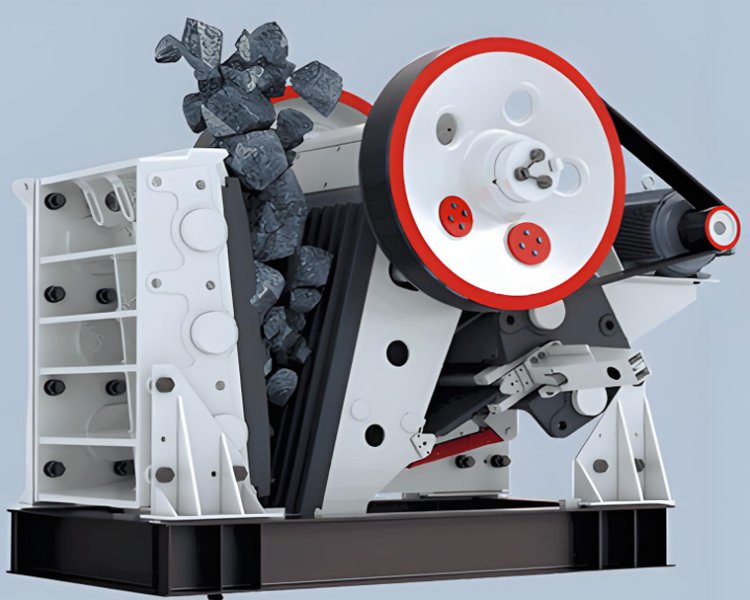

Jaw Crusher

239Diversity of crusher materialsHow does a jaw crusher workMobile jaw crusher Structure CompositionWhy Mining Machinery Recommends Jaw Crusher The working principle of the jaw rock crusher is based on th...

View detailsSearch the whole station

Definition of Fly Ash Brick Making Machine

Brick-making machine is a kind of mechanical equipment specialized in producing various types of bricks. It produces bricks that meet the specifications by mixing, molding and pressing the raw materials (such as clay, cement, gravel, concrete, sand and plastic, etc.) through the process.

Brick making machine is widely used in construction, roads, gardens and other fields, is an indispensable and important equipment in modern construction industry.

Brick-making machines, with their highly flexible forming technology and broad adaptability to raw materials, have become core equipment in the modern building materials industry. Their applications span four major fields: municipal engineering, ecological construction, industrial recycling

And civil construction: In municipal engineering, they can efficiently produce high-strength pavement bricks, permeable bricks, and curbstones, meeting the durability and drainage requirements of urban roads, squares, and parks; In ecological construction, custom molds can be used to produce ecological products such as hydraulic slope protection bricks and grass-paving bricks, supporting river management and greening projects;

In industrial recycling, the equipment can convert construction waste, fly ash, and slag into recycled building materials, achieving a resource recycling rate exceeding 70%; In the residential construction market, standard bricks, hollow bricks, and decorative bricks are widely used to meet the diverse needs of residential and commercial complexes.

The equipment’s non-fired production process enables a single production line to achieve an annual output of over 100 million bricks, making it a key pillar of green infrastructure development.

The hydraulic brick press machine presses the bricks through the pressure generated by the hydraulic cylinder, the pressure can reach 200t, which can significantly improve the density and strength of the bricks, reduce the breakage rate during transportation, and at the same time improve the durability of the bricks in the process of use.

The use of multiple pressurization and exhaust process, such as four pressurization and three exhaust, can maximize the exclusion of air in the powder, so that the strength of the brick is further improved, the shrinkage rate is lower, and it is not easy to produce cracks.

Hydraulic red brick machine adopts full automation program setting, which can save labor and working hours and increase the output.

Intelligent Brick Making Machine has high-frequency and low-amplitude table vibration with adjustable frequency, which ensures stable molding results for concrete making pieces of various shapes and sizes.

Combined with a mixer and a conveyor belt, it can form a brick-making production line and improve production efficiency.

Fully automatic concrete brick making machine has silent and static pressure mode, comparing with traditional brick machine, the noise is effectively reduced.

Join the imported pneumatic damping system, can greatly reduce the noise generated by the vibration motor work and the adverse effects on the various parts of the machine, enhance the service life and stability of the machine.

The paving brick machine can use industrial waste residue (such as coal dust ash, coal gangue, slag, smelting slag and all kinds of tailing slag) as the main raw material to realize waste recycling and reuse, which is more environmentally friendly and energy-saving.

Clay brick press machine produces a wide range of products, can produce thickness in the range of 50-250mm range of clay cement concrete products, and the products have good compactness, high strength, frost resistance, good seepage resistance, sound insulation, heat insulation, heat preservation performance is excellent.

| Small Brick Press Machine | Molding cycle (s) | Single block size (mm) | Shift production (blocks) | Weight of the whole machine (kg) |

| XD-2-45 | 45 | standard brick 240*53*115 hollow brick 390*190*190 | 3600/600 | 200 |

| XD-3-45 | 45 | standard brick 240*53*115 hollow brick 390*190*190 | 8000/1000 | 300 |

| XD4-35A | 35 | standard brick 240*53*115 hollow brick 390*190*190 | 15000/2400 | 750 |

| XD4-35B | 35 | standard brick 240*53*115 hollow brick 390*190*190 | 20000/3200 | 780 |

| XD4-30A | 35 | standard brick 240*53*115 hollow brick 390*190*190 | 15000/2400 | 800 |

According to the customer’s needs to customize the brick making machine model, free delivery of trolleys and other accessories.

Chinese brick making machines represent a convergence of engineering precision, environmental responsibility, and economic viability. By leveraging these advanced technologies, international buyers can not only enhance their production capabilities but also contribute to global sustainable development goals.

As the industry continues to innovate, early adopters of these smart manufacturing solutions will gain a decisive competitive edge in the global construction materials market.

Diversity of crusher materialsHow does a jaw crusher workMobile jaw crusher Structure CompositionWhy Mining Machinery Recommends Jaw Crusher The working principle of the jaw rock crusher is based on th...

View details