How does a small box type cake press work

367A small box type cake press is a machine specifically designed for pressing metal waste

View detailsSearch the whole station

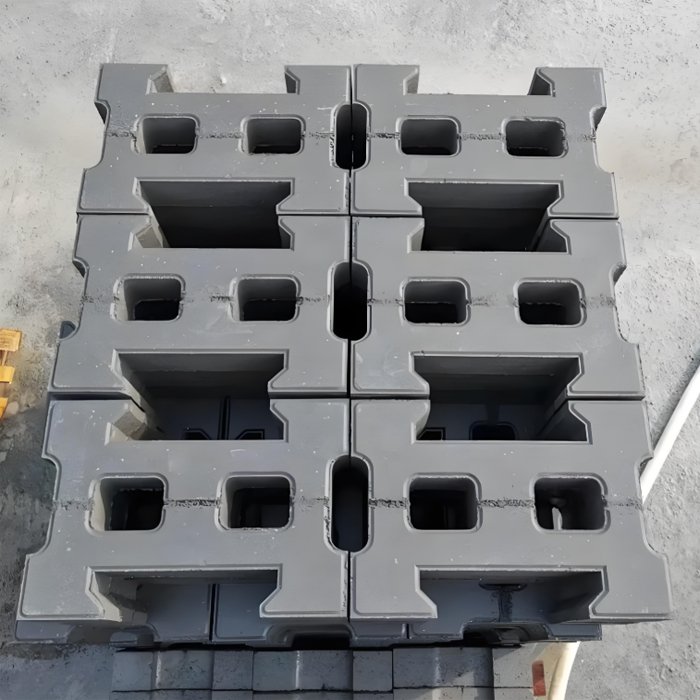

Brick making machine is a mechanical equipment that produces building bricks through a specific process, the raw material can be used cement, concrete, aggregate, and many other options.

| Types of bricks | Main raw-material (bulky,accounting for 55%-100% ofthe raw materials requirements) | Other raw-materials |

| Cement bricks, fly ash bricks, concrete bricks | Pulverised fuel ash (fly ash from thermal power plants) | Sand, cement, lime, gypsum, |

| Hollow Concrete blocks | Stone chips (coarse aggregate) | sand or stone-dust (fine aggregate), cement |

| Solid burnt clay, perforated burntclay, hollow burnt clay blocks, | Brick earth/ clay | Coal as fuel (for burnt-clay products) Cement |

While traditional bricks are based on clay, sand and lime, modern processes widely use alternative materials such as fly ash, industrial wastes and cement. Eco-bricks and special function bricks (e.g. hollow, interlocking turn, heat insulation) will introduce raw materials such as plastics, rice husk ash and fibers.

The selection of raw materials needs to take into account the cost, environmental protection and performance requirements of the brick body, while improving the quality and yield of bricks through the optimization of ratios and additives, and implementing large-scale production.

If you’re interested in our brick-making machines, contact us immediately!

A small box type cake press is a machine specifically designed for pressing metal waste

View detailsWhat Is a Metal Shredder?Types of Metal ShreddersApplications of Metal Shredders Metal shredders are essential machines in the recycling and waste management industries. They are designed to reduce large pieces of metal into smaller, more manageab...

View detailsThe bicycle crocodile shearing machine is mainly used as a device for cold shearing various shapes of steel and metals, including bicycle racks

View detailsWhat is a Metal Recycling Shredder?Factors Affecting the Cost of Metal Recycling ShreddersAverage Cost of Metal Recycling Shredders in 2026Benefits of Investing in a Metal Recycling ShredderTop Metal Recycling Shredders on the MarketFrequently Ask...

View details