What are the uses of metal compactors

652Metal compactor is an efficient and energy-saving equipment widely used in the field of metal material processing and reuse.

View detailsSearch the whole station

Yes, it is absolutely possible to shred plastic. In fact, it is the most critical first step in nearly every plastic recycling process. The more important question for your business is not if it’s possible, but how you can do it efficiently and profitably. We are Fude Machinery, a specialized manufacturer of plastic shredder machines. We are here to show you how shredding plastic is not just possible, but a smart business decision that can save you money and create new revenue.

You shred plastic to turn a costly waste problem into a valuable asset. Unprocessed plastic waste is bulky, difficult to handle, and expensive to transport or send to a landfill. Shredding it with an industrial plastic shredder immediately changes this reality. It is a process that creates value in several key ways.

As a B2B importer of equipment, you are looking for investments that deliver a clear return. Shredding plastic does exactly that. For manufacturers, it means reclaiming your own scrap to reduce raw material costs. For recycling companies, it means taking in low-value waste and converting it into a sellable commodity. The business case is straightforward and powerful.

| Scenario | Before Shredding | After Shredding | How This Benefits Your Business |

|---|---|---|---|

| Storage | Waste takes up a huge amount of factory floor or yard space. | Volume is reduced by up to 90%. Shredded material is dense and compact. | You free up valuable space for production or other operations. |

| Transport | You are paying to transport mostly air in hollow or bulky items. | You can fit many times more material into a single truck or container. | Your logistics and shipping costs drop significantly. |

| Disposal | You pay landfill fees based on the volume or weight of your waste. | Disposal costs are minimized or completely eliminated. | You stop spending money to throw away a potentially valuable resource. |

| Value | Plastic waste is a liability with a negative or zero value. | Shredded plastic becomes a uniform, easy-to-handle raw material. | You can reuse it in your own production or sell it to other companies for a profit. |

Practically every common type of rigid and flexible plastic can be shredded. A key advantage of modern shredder equipment is its versatility. Different machines are optimized for different materials, but the technology exists to process almost any plastic waste stream. That is why our first question to a new client is always, “What specific materials are you working with?”

At Fude Machinery, we engineer our machines to handle specific material properties. Whether your plastic is hard and brittle or soft and stretchy, there is a shredding solution for it. We design and build these machines ourselves, so we can configure the blades, rotor speed, and power to perfectly match your needs.

A plastic crusher breaks down bulky plastic waste (such as bottles, containers, films, lumps, and sprues) into small, uniform granules through mechanical force. The process involves:

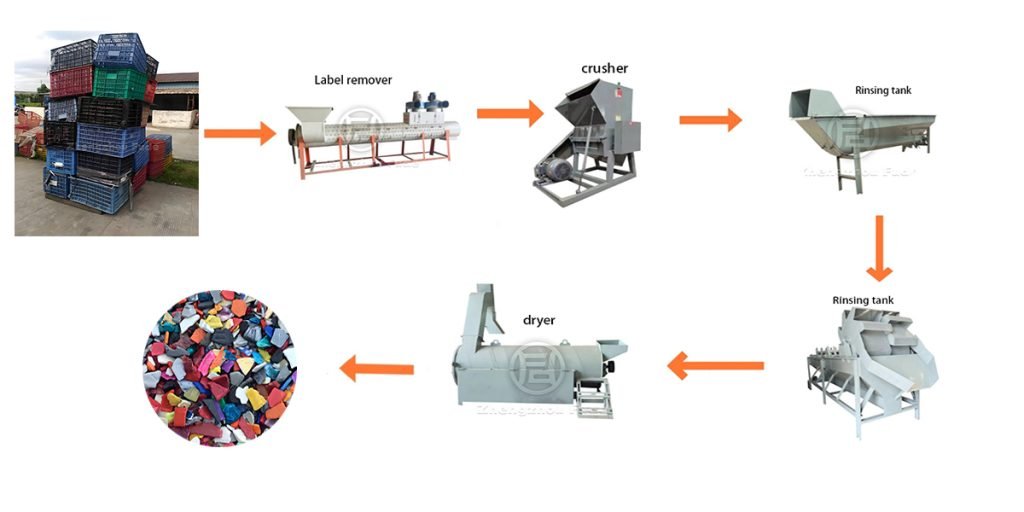

Shredding is the first step. The shredded plastic is then usually washed, dried, and turned into pellets. The initial shredding process creates rough, fist-sized flakes or strips. This material is now in a perfect form for the next stages of recycling. It is easier to handle, easier to clean, and easier to feed into other machines.

As a company that provides complete plastic recycling lines, we see the full journey. After our shredder does its job, the material typically goes through this process:

1. How small can the plastic be shredded?

The output size depends on the machine type. A double-shaft shredder’s output is determined by the width of its blades, typically producing strips 20mm-50mm wide. A single-shaft shredder uses a screen, so you can control the output size more precisely, often down to 20mm. For even smaller sizes, a secondary plastic crusher is needed.

2. Does it use a lot of electricity?

Industrial shredders use powerful motors, so they do consume a significant amount of electricity when operating. However, modern designs and efficient gearboxes help to optimize power usage. The cost of electricity is far outweighed by the value created and the savings on disposal and transport.

3. What if there is metal mixed in with the plastic?

This is a common issue. Our shredders are built with robust, hardened steel blades and have automatic reverse functions. If the machine senses an object it cannot shred (like a piece of heavy steel), the shafts will stop, reverse for a moment, and then try again. This helps prevent major damage to the blades.

4. Is it possible to shred different types of plastic at the same time?

Yes, a shredder can process mixed plastics. However, for high-value recycling, the resulting material will have little value because the plastic types are co-mingled. It is usually best to sort plastics by type before shredding if you intend to sell the output material.

So, is it possible to shred plastic? Yes, and it is one of the most practical and profitable steps any business dealing with plastic waste can take. It transforms a bulky, costly problem into a compact, valuable resource. By using the power of high-torque machines, you can process almost any type of plastic waste, preparing it for a new life and creating a positive return for your business.

The key to success is using the right machine for the job. Partnering with a manufacturer who understands the nuances of different plastics and applications ensures you get an asset that works reliably for years.

Ready to explore how shredding plastic can benefit your business?

Let’s talk about your specific materials and goals. Contact the Fude Machinery team today. We provide factory-direct pricing and expert engineering advice to help you build a profitable recycling operation from the ground up.

Contact Fude Machinery for your expert consultation!

Metal compactor is an efficient and energy-saving equipment widely used in the field of metal material processing and reuse.

View detailsThis article explores the different types of waste disposal units, factors that influence their cost, and provides a detailed breakdown of prices. We will also introduce Fude Machinery’s line of industrial metal crushers and briquetting equipment,...

View detailsHow does the ultra-high compression ratio help you save amazing amounts on storage and transport costs?Beyond volume reduction, how does briquetting performance directly increase scrap value and selling price?How much potential loss can efficient ...

View detailsBenefits of Heavy Duty Metal ShreddersHow to Choose the Best Metal Shredder MachineTop 8 Best Heavy Duty Metal Shredder MachinesSummary Table of Top Metal ShreddersConclusion Metal recycling is a cornerstone of sustainable manufacturing and indust...

View details