Heavy metal crusher

A machine for crushing waste metal materials

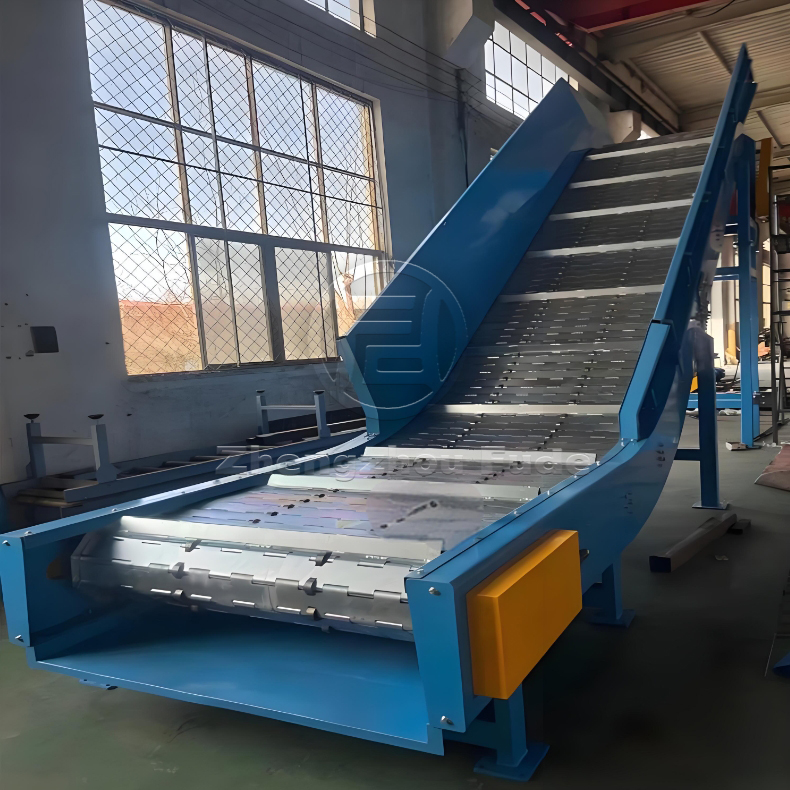

The crusher mainly consists of a feeding bin, crushing double rollers, power distribution control system, discharge conveyor, and power transmission device.

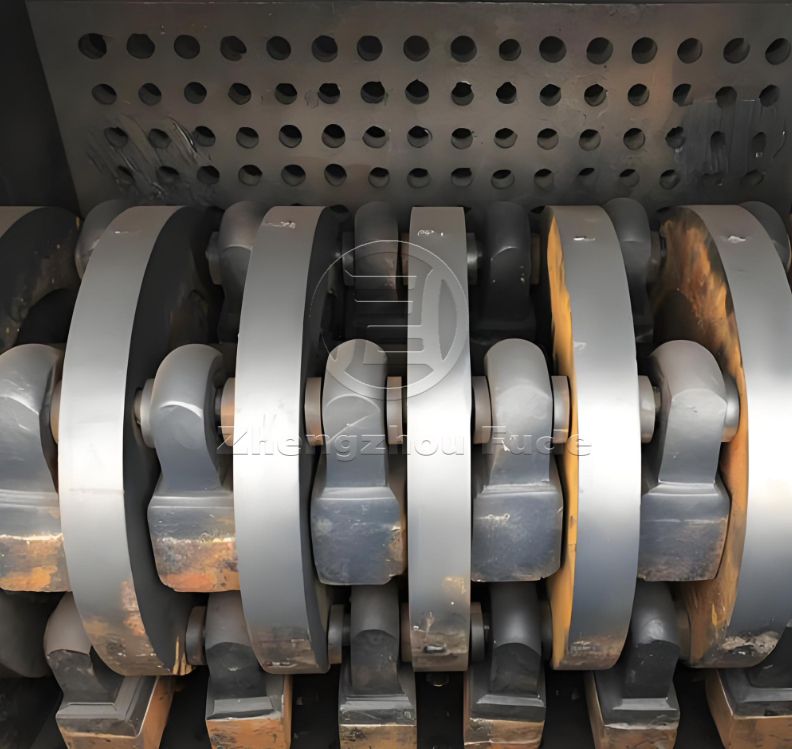

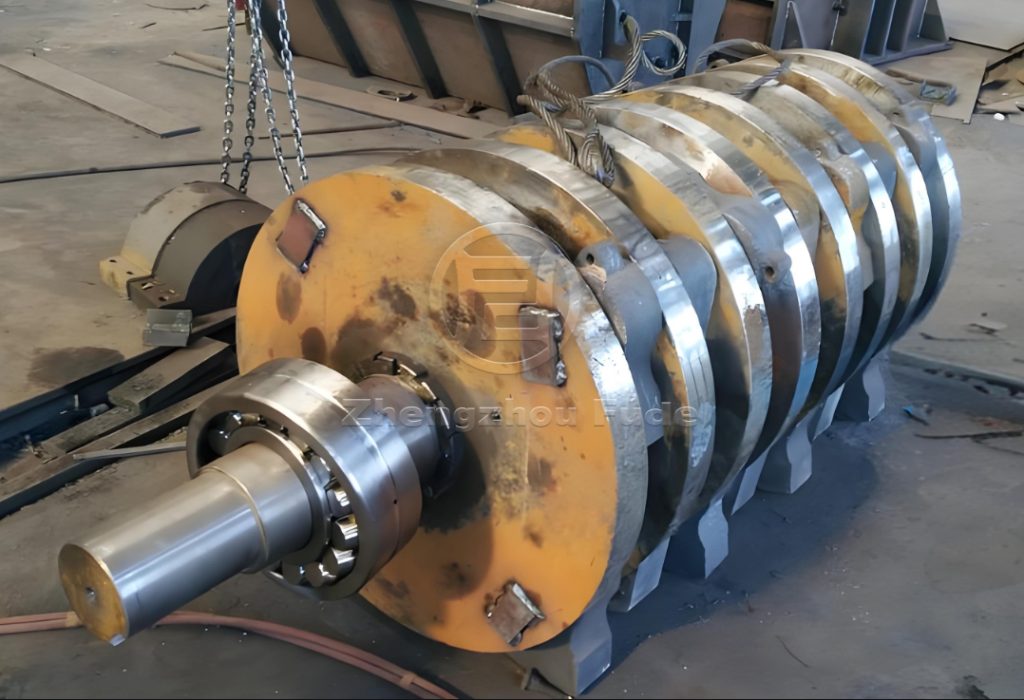

The double rollers are equipped with wear-resistant cutting tools. After all the cutterheads are assembled, a spiral knife is formed.

After rotation, it ensures that each cutterhead is subjected to uniform stress and crushes the material through the deflection of the hook of the knife and the compression between the double rollers.

In the realm of industrial metal recycling and processing, heavy metal shredders have emerged as indispensable equipment, revolutionizing the way we handle and repurpose scrap metal.

These powerful machines are designed to efficiently break down various types of metal waste into manageable sizes, facilitating easier transportation, storage, and further processing.

Metal crusher operation video

The metal ball crusher machine consists of a feeding bin, crushing double rollers, power distribution control system, discharge conveyor, and power transmission device.

The double rollers are equipped with wear-resistant cutting tools, and after all the cutterheads are assembled, they form spiral knives.

After rotation, it ensures that each cutterhead is subjected to uniform stress and crushes the material through the deflection of the hook of the knife and the compression between the double rollers.

| Name | Metal crusher | Application area | Scrap metal recycling and processing |

| Yield | 1T-8T | Model | 600, 800, 2000 models, etc |

Heavy duty metal crusher product introduction

A heavy metal shredder, also known as a metal crusher or metal shredding machine, is a robust industrial device engineered to shred and reduce the size of metal waste materials.

These materials include but are not limited to scrap cars, bicycles, motorcycles, appliances, steel drums, aluminum cans, and other metal debris. By applying mechanical force through rotating blades or hammers, the shredder tears the metal into smaller pieces, making it easier to handle and process.

It has the advantages of high output, low energy consumption, high efficiency, and uniform discharge crushing. Widely used in industries such as smelting and renewable resources to improve the efficiency of waste metal resource treatment and increase the recycling rate of waste resources.

Metal crusher

Metal crusher

Metal crusher

Scrap metal crusher scope of application

Scrap metal crusher Applicable objects: bicycles, motorcycles, car casings, scrap steel, cans, paint buckets, iron sheets, color steel tiles, light and thin metal materials, etc.

- Scrap Metal Recycling: Heavy metal shredders play a crucial role in the scrap metal recycling industry. They help recyclers break down large metal objects into smaller pieces, making it easier to sort, transport, and process the materials for reuse.

- Automotive Industry: In the automotive sector, heavy metal shredders are used to dismantle and recycle end-of-life vehicles. The shredded metal can be separated from other materials, such as plastics and rubber, and sent for further processing.

- Construction and Demolition: During construction and demolition projects, heavy metal shredders are employed to break down metal debris, such as rebar, pipes, and structural beams. This facilitates the cleanup process and enables the recycling of valuable metal resources.

- Manufacturing: In manufacturing plants, heavy metal shredders are used to dispose of metal waste generated during production processes. The shredded metal can be recycled or sold as scrap, reducing waste disposal costs and promoting sustainability.

Metal crusher

Metal crusher

Metal crusher

Metal crusher

Metal crusher

Metal crusher

Waste large metal crusher product features

- The blade of a metal crusher is a mesh type blade refined from high alloy, which has a good crushing effect on any high hardness material.

- The Large industrial crusher is driven by a deceleration motor, which saves 20% of electricity compared to other can crushers.

- The metal crusher starts smoothly without too much noise, and is installed with a foundation, making the noise very low.

- The Industrial Crusher has a strong and sturdy structure, with densely distributed stiffening plates to ensure the strength of the box.

- The metal crusher can be equipped with conveyor belt feeding equipment.

- The all-round control button makes your operation simpler, and the entire crushing process only requires one person.

Working principle of large industrial metal crusher

The core principle of a metal crusher is to use a hammer to strike metal materials. Driven by a high-speed and high torque motor, the hammer head on the main rotor alternately impacts the material to be crushed into the chamber, tearing it apart into compliant fragments through the space formed between the lining plate and the hammer head.

According to the working conditions of the crusher, it can be divided into dry system, wet system, and semi wet system. The drying system mainly refers to the process of separating metal and non-metal materials through an air rotary sorting system, and the entire system is equipped with a dust removal device.

Wet system refers to the process of spraying water during crushing and cleaning during sorting. The semi wet system only sprays a small amount of water when it needs to be crushed to prevent dust, without cleaning.

Industrial Metal Crusher:Different material crushing effects

The size of broken particles varies according to user needs, and the size of particles can be changed by changing the screen mesh

Hammer head

Screen mesh

Rotor

Crushing effect of scrapped cars

Crushing effect of colored steel tiles

Scrap steel crushing

Effectiveness of crushing aluminum cans

Key Features of Heavy Metal Shredders

- High-Efficiency Shredding: Heavy metal shredders are equipped with powerful motors and precision-engineered blades that can handle large volumes of metal waste with ease. The high-speed rotation of the blades ensures rapid and efficient shredding, reducing processing time and increasing productivity.

- Versatility: These shredders are designed to process a wide range of metal materials, from thin sheets to thick chunks. Some models even come with adjustable settings, allowing operators to customize the output size according to specific requirements.

- Durable Construction: Built to withstand the rigors of industrial use, heavy metal shredders feature robust frames and reinforced components. This ensures longevity and reliability, even under continuous operation.

- Safety Mechanisms: Safety is paramount in industrial settings, and heavy metal shredders are no exception. Many models incorporate safety features such as emergency stop buttons, overload protection, and enclosed shredding chambers to prevent accidents and protect operators.

- Environmental Friendliness: By reducing metal waste into smaller, more manageable pieces, heavy metal shredders contribute to environmental sustainability. The shredded metal can be easily transported to recycling facilities, where it can be melted down and repurposed into new products, reducing the need for raw material extraction.

metal crusher for sale

We have comprehensively consulted and followed up on the experiences of customers in the United States, South Korea, India, Russia, Australia, and other countries regarding the use of metal crushers, and they have provided particularly satisfactory responses.

Broken color steel tiles for American customers

Indian customer on-site crushing paint bucket

Korean customers crushing plastic waste

Russian customer crushing scrap car site

Benefits of Using Heavy Metal Shredders

- Cost Savings: By shredding metal waste into smaller pieces, heavy metal shredders reduce transportation and storage costs. The shredded metal takes up less space, allowing for more efficient use of storage facilities and transportation vehicles.

- Increased Productivity: The high-efficiency shredding capabilities of heavy metal shredders enable faster processing of metal waste, increasing overall productivity. This is particularly beneficial in industries with high volumes of metal waste, such as scrap metal recycling and automotive dismantling.

- Environmental Protection: Heavy metal shredders contribute to environmental protection by promoting the recycling of metal resources. By reducing the need for raw material extraction, these machines help conserve natural resources and reduce greenhouse gas emissions associated with mining and refining processes.

- Enhanced Safety: The safety mechanisms incorporated into heavy metal shredders protect operators from potential hazards, such as flying debris and machine malfunctions. This ensures a safer working environment and reduces the risk of accidents and injuries.

Metal Crusher Manufacturer:Factory loading and shipping site

How to choose a suitable metal crusher

Firstly, you need to determine the type and size range of materials to be processed; Secondly, consider processing capacity and production demand; Thirdly, understand the tool structure and durability of metal crushers; Fourthly, consider the safety and maintenance convenience of metal crushers; Finally, consider the cost and after-sales service of the metal crusher.

Choose a cost-effective metal crusher based on budget and specific needs. We can also customize suitable models according to the specific needs of customers, which can improve their production efficiency.

Heavy metal shredders are essential equipment in the field of metal recycling and processing. Their high-efficiency shredding capabilities, versatility, durability, and safety features make them ideal for a wide range of applications.

By using heavy metal shredders, industries can achieve cost savings, increased productivity, environmental protection, and enhanced safety. As the demand for sustainable metal recycling solutions continues to grow, heavy metal shredders will play an increasingly important role in shaping the future of the industry.

Fudemetal Crusher

Fudemetal Crusher