Waste paper baler

A multifunctional hydraulic waste paper packaging machine

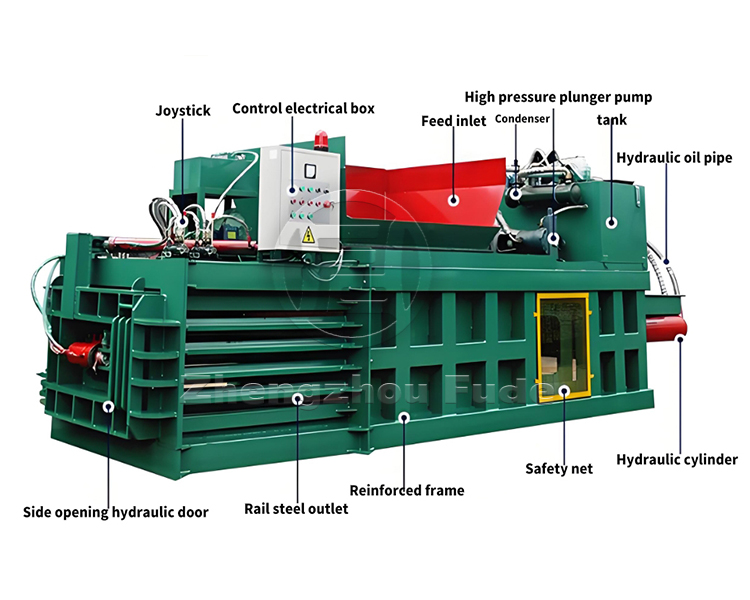

The fully automatic waste paper packaging machine is an electromechanical integrated and highly automated packaging machine, mainly composed of mechanical systems, control systems, feeding systems, and power systems.

The fully automatic hydraulic packaging machine has the characteristics of good rigidity, toughness, stability, beautiful appearance, convenient operation and maintenance, safety and energy conservation, and low investment cost in equipment foundation engineering.

In an era where environmental sustainability is at the forefront of global consciousness, effective waste management and recycling have become paramount.

Among the various tools facilitating this green revolution, horizontal waste paper balers stand out as indispensable equipment for businesses and recycling centers worldwide.

Working video of waste paper packaging machine

The waste paper packaging machine uses hydraulic cylinders to compress materials;

During the work process, the rotation of the motor drives the oil pump to work and extract hydraulic oil from the oil tank;

Then, it is transported through hydraulic oil pipes and transmitted to each hydraulic cylinder, driving the piston rod of the cylinder to move longitudinally and compressing various materials in the material box.

Product parameters of horizontal packaging machine

| Model | Pressure | Bag size(mm) | Yield | Package weight |

| 120 | 1200kn | 1050*1150*1300 | 6 | 450kg |

| 160 | 1600kn | 1150*1250*1500 | 8 | 1100kg |

Horizontal Waste Paper Baler Product Introduction

Horizontal waste paper balers are specialized machines designed to compress and package waste paper, cardboard, plastic bottles, and other recyclable materials into compact, manageable bales. Unlike vertical balers, which compress materials from the top down, horizontal balers work by applying pressure horizontally, allowing for larger volumes of material to be processed continuously. This makes them ideal for high-capacity recycling operations where efficiency and throughput are critical.

Key Benefits of Horizontal Waste Paper Balers

- Increased Efficiency: Horizontal balers can process large volumes of waste material quickly and continuously, significantly increasing recycling efficiency. Their high throughput rates make them ideal for busy recycling centers and manufacturing facilities.

- Reduced Storage and Transportation Costs: By compressing waste materials into compact bales, horizontal balers reduce the volume of waste by up to 80% or more. This not only saves valuable storage space but also lowers transportation costs, as fewer trips are required to move the same amount of material.

- Enhanced Safety: Horizontal balers are designed with safety in mind, featuring emergency stop buttons, overload protection, and safety guards to prevent accidents and injuries. Their automated operation also reduces the need for manual handling of waste materials, further minimizing safety risks.

- Environmental Sustainability: By facilitating the recycling of waste paper and other materials, horizontal balers contribute to environmental sustainability by reducing landfill waste and conserving natural resources. They play a crucial role in the circular economy, promoting the reuse and recycling of materials.

- Versatility: While primarily designed for waste paper and cardboard, horizontal balers can also handle a wide range of other materials, including plastic bottles, textiles, and even thin metal scraps. This versatility makes them a valuable asset for businesses with diverse recycling needs.

Horizontal packaging machine with chain plate feeding machine

Single machine waste paper packaging machine

Product Features of Scrap Baler

- Feeding port: The feeding port is designed with a widened width, which can be filled with materials in one go, making it convenient and fast.

- Remote distribution box: Convenient and fast, with two control methods and safer and more convenient handle control.

- High quality reinforced frame: Long term use without deformation, high strength of frame weft overlap, no welding.

- Thickened body: The entire machine is made of high-quality steel and thickened steel plates, which have strong pressure resistance and are sturdy and durable.

Feed inlet

Remote distribution box

High quality reinforced frame

Thickened body

Advantageous product characteristics of waste paper compressors

- All models are hydraulic driven and can be manually or PLC automatically controlled.

- There are different ways of discharging materials, such as flipping the bag, pushing the bag (side pushing and forward pushing), or manually picking up the bag (packaging).

- Installation does not require foot screws, and diesel engines can be used as power in areas without power supply.

There are ten levels of extrusion pressure from 63 tons to 400 tons for users to choose from, with production efficiency ranging from 4 tons per shift to 40 tons per shift. - The size of the compression chamber and package block can be customized according to customer requirements.

- The push cylinder and push head are connected by a spherical structure, which has good reliability and long service life of the oil seal.

- The feeding port is equipped with a dispersed shear knife, which has good cutting efficiency.

- Low noise hydraulic circuit design.

- Easy installation without foundation.

- Horizontal structure, can be equipped with conveyor belt feeding or manual feeding.

- Button operation, PLC control.

Large multifunctional conveying and packaging integrated machine

Key Considerations for Selecting a Horizontal Waste Paper Baler

When choosing a horizontal waste paper baler, several factors should be taken into account to ensure optimal performance and cost-effectiveness:

- Capacity and Throughput: Assess the volume of waste material your facility generates daily and select a baler with a suitable compression capacity and throughput rate. Overestimating or underestimating your needs can lead to inefficiencies or unnecessary expenses.

- Bale Size and Weight: Consider the size and weight of the bales you wish to produce, as this will impact storage, handling, and transportation requirements. Larger bales may be more cost-effective to transport but may require specialized equipment for handling, while smaller bales offer greater flexibility but may increase transportation costs.

- Automation Level: Decide on the desired level of automation based on your budget and operational requirements. Fully automated balers offer greater efficiency and convenience but come at a higher cost, while semi-automated or manual models may be more suitable for smaller operations with limited resources.

- Maintenance and Support: Choose a baler from a reputable manufacturer that offers comprehensive maintenance and support services. Regular maintenance is essential to ensure the longevity and optimal performance of your baler, and prompt technical support can minimize downtime in the event of a breakdown.

- Energy Efficiency: Consider the energy consumption of the baler and look for models with energy-saving features, such as variable-speed drives and efficient hydraulic systems. This can help reduce operating costs and minimize your environmental impact.

Working principle of waste paper briquette machine

- Loading: Load bulk waste paper into the packaging machine and adjust its position.

- Compression: Start the hydraulic system, the oil pump presses the liquid into the hydraulic cylinder, and drives the pressure head downwards to compact the waste paper, gradually becoming a compaction block.

- Release the pressure head: When the pressure head reaches the preset pressure, stop pressurizing, release the hydraulic cylinder, and remove the compacted waste paper block.

- Binding: Use steel wire or woven bags to bundle the compacted waste paper blocks to prevent scattering.

Structure of the packaging machine body

Wide range of applications for waste paper compactors

Suitable for compressing and packaging all light foam, loose materials, and other soft materials such as straw, grass, waste cardboard boxes, cotton, clothing, plastic, woven bags, fabrics, recyclable garbage, etc.

Easy to pull can

After packaging

Straw straw

After packaging

Plastic bottles

After packaging

Scrap metal

After packaging

Horizontal waste paper balers find applications in a multitude of sectors, including:

- Recycling Facilities: These centers rely on horizontal balers to process large volumes of collected waste paper, cardboard, and plastic films, preparing them for sale to recycling mills. The compacted bales are easier to handle, store, and transport, improving overall operational efficiency.

- Manufacturing Plants: Many manufacturing processes generate significant amounts of waste paper and cardboard as byproducts. Horizontal balers enable these facilities to manage their waste effectively, reducing disposal costs and promoting a cleaner, more sustainable production environment.

- Printing and Publishing Houses: The printing industry produces vast quantities of waste paper during production runs. Horizontal balers help printing houses compress and package their waste for recycling, minimizing their environmental footprint and potentially generating revenue from the sale of recyclable materials.

- Logistics and Warehousing: In logistics and warehousing operations, horizontal balers are used to compress and package waste materials generated during packaging, shipping, and receiving processes. This helps maintain a clean and organized workspace while facilitating efficient waste disposal.

- Retail and Supermarket Chains: Retailers and supermarkets generate substantial amounts of cardboard waste from product packaging. Horizontal balers enable these businesses to compress their waste on-site, reducing the frequency of waste collections and lowering associated costs.

Waste paper baler machine price with favorable price

We consulted and followed up with customers from the United States, Japan, South Korea, and India regarding their satisfaction with the use of the packaging machine, and they provided very satisfactory responses.

US customer packaging waste cardboard boxes on-site

Indian customers pack straw and straw

On site for Japanese customers to pack discarded packaging bags

Korean customer packaging waste plastic bottles on-site

Horizontal waste paper balers are powerful tools for promoting environmental sustainability and efficient waste management. Their ability to compress and package waste materials into compact bales makes them invaluable for businesses and recycling centers worldwide.

By understanding their functionality, benefits, applications, and key considerations for selection, you can choose the right horizontal baler to meet your specific needs and contribute to a greener, more sustainable future.

Fudemetal Crusher

Fudemetal Crusher