Many businesses see their metal scrap as a messy, low-value byproduct that costs money to get rid of. But what if you could change that? We want to share a real case study. It shows how one of our clients used a Fude metal briquetting machine to transform a costly waste problem into a significant new source of profit. This story proves that with the right equipment, you can turn your industrial waste into treasure.

The Problem: What Challenges Was Our Client Facing Before?

Our client, a mid-sized automotive parts manufacturer, was drowning in metal scrap. Every day, their CNC machines produced tons of loose, oily steel turnings. This created several big problems for their business. Their workshop floor was constantly cluttered and messy. This took up valuable space. It also created safety hazards for their employees. Loose, sharp metal chips and slippery, oily floors were a daily concern.

Their biggest issue was the cost. They were paying a disposal company a large fee every month just to haul the scrap metal away. On top of that, they were losing all the expensive cutting oil that was mixed in with the turnings. This was like throwing money away.

They were also heavily dependent on buying new, expensive steel to feed their production lines. The fluctuating price of raw materials made it very difficult to manage their budget. They knew there had to be a better way to handle their scrap.

The Solution: Why They Chose a Fude Metal Briquetting Machine

After researching their options, the client decided to invest in a Fude Machinery metal chip briquetting machine. They chose us for several key reasons. First, we didn’t just try to sell them a standard machine. We listened carefully to their specific needs.

We understood they were dealing with steel turnings and needed a solution that could also handle oil recovery. We proposed a custom-configured machine that was perfect for their material type and output volume. This is a core part of our business—providing tailored solutions.

Second, they were impressed by our full-service support. As a manufacturer, we offer more than just equipment. We helped them with the entire process. This included designing the layout, installing the machine, and training their staff. Third, our technology stood out.

Our metal briquetting machine features a robust hydraulic system for high-density compaction. It also has an intelligent PLC control system for easy, automated operation. The built-in fluid collection system was exactly what they needed for oil recovery. Finally, because they bought directly from us, the manufacturer, they received a highly competitive price. This made the investment more affordable.

The Implementation: How Did We Make It Happen for Them?

We worked closely with the client to ensure a smooth and successful implementation. Our technical team visited their factory. We helped them find the best location for the new machine. We designed a layout that integrated seamlessly with their existing workflow.

We installed a conveyor belt to automatically feed the steel turnings from their production area directly into the briquetter’s hopper. This minimized manual labor.

Once the machine was installed, our engineers commissioned it. We made sure it was running perfectly. We then provided comprehensive training for their operators. We taught them how to use the PLC controls, perform daily checks, and follow safety procedures.

The entire process was collaborative. We made sure they were confident and ready to get the most out of their new investment. Our goal is to be a partner, not just a supplier. Our complete production lines reflect this partnership approach.

The Results: The Amazing Transformation and Financial Impact

The results were transformative and exceeded the client’s expectations. Within just a few months, their entire waste management process changed. The once cluttered workshop became clean and organized. But the most impressive results were the financial ones. The investment in the metal briquetting machine paid for itself much faster than they had imagined.

This case study is a powerful example of “waste to treasure.” By investing in the right technology, the client eliminated a major cost center. They created two new revenue streams (selling briquettes and saving oil). They also made their operations safer and more efficient.

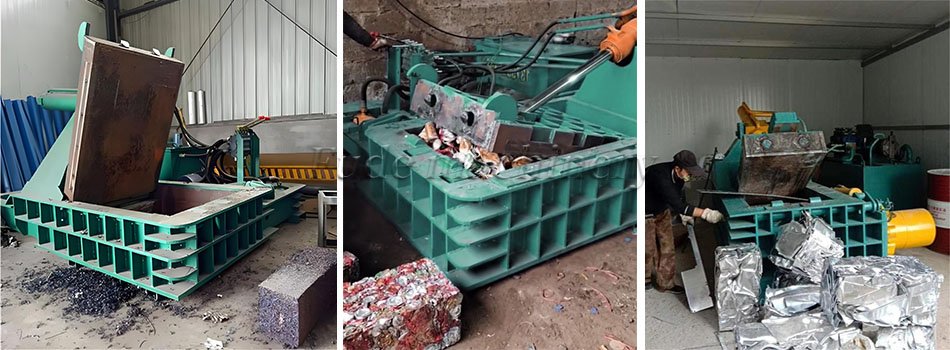

For handling different kinds of scrap, our hydraulic baler offers another effective solution.

Beyond This Case: How Can These Benefits Apply to Your Industry?

The success of this automotive parts manufacturer is not unique. The principles of turning waste into value with a metal briquetting machine apply across many different industries. The specific benefits might vary slightly, but the core advantages remain the same.

For Metal Foundries and Casting Plants

If you run a foundry, your main goal is to produce high-quality metal parts. You probably generate a lot of your own scrap, like aluminum chips or cast iron filings. Instead of selling this scrap for a low price, you can use our machine to press it into high-density briquettes. You can then feed these briquettes directly back into your own furnaces. The high density ensures a better melt rate and higher metal recovery. You directly replace the need to buy expensive primary metals like pig iron or aluminum ingots. This creates a closed-loop recycling system within your own factory, giving you huge cost savings and control over your material quality.

For Scrap Recycling Yards

If you are in the business of recycling metal, your profit margin is everything. You likely buy loose, low-value scrap from various sources. A metal briquetting machine is a powerful tool for you to upgrade this material. You can take messy, bulky scrap metal that is hard to sell. You can process it into clean, dense, uniform briquettes. These briquettes are a standardized product. They are much more attractive to large foundries and steel mills. They will pay a premium price for them. This allows you to significantly increase the value of the material you handle, boosting your profits on every ton you process.

Common Questions and Answers

Question 1: How much operator training is needed to run the machine?

Very little. Our metal briquetting machine is designed with a user-friendly PLC control system. Once we set it up for your material, day-to-day operation is mostly automated. We provide full training, and most operators feel comfortable running the machine within a day.

Question 2: Does this process work for other metals like aluminum or copper?

Absolutely. Our machines are designed to handle a wide range of metals. This includes steel, cast iron, aluminum, copper, brass, and more. We can configure the machine’s pressure and cycle time to be optimal for the specific metal you are processing.

Question 3: What was the biggest challenge the client in the case study faced during the transition?

The biggest challenge was changing their internal workflow. They had to create a new process for collecting scrap and moving it to the briquetter. However, with our help in designing the layout and installing a conveyor, this transition was very smooth. The long-term benefits far outweighed the short-term adjustment.

Summary and Recommendations

This real-world case study clearly shows that a metal briquetting machine is not just a piece of equipment; it is a strategic investment in your business’s profitability and sustainability. Our client successfully transformed a major expense into a significant profit center. They achieved a remarkable return on investment in just 18 months. They did this by eliminating disposal costs, creating new revenue from scrap, and saving money on valuable cutting oil.

We invite you to think about your own scrap metal situation. Are you paying to have it removed? Are you losing valuable fluids? A Fude Machinery briquetting solution could offer you similar transformative results. It is a proven way to make your operations more efficient, more profitable, and more environmentally friendly.

About Fude Machinery

We are Fude Machinery, a professional manufacturer based in China specializing in scrap metal processing machinery. Since 2015, we have been helping businesses worldwide turn their waste into value. Our product line includes the metal briquetting machine, hydraulic balers, and complete, customized production lines. We are a B2B-focused company that prides itself on quality, innovation, and full-service support. Our products are trusted by clients in over 120 countries.

Are you ready to write your own success story? Contact Fude Machinery today for a free consultation. Let’s discuss how we can help you turn your scrap metal problem into a profitable opportunity.

Fudemetal Crusher

Fudemetal Crusher