Large shredder production line

Scrap iron, scrap steel, various waste shredding production line

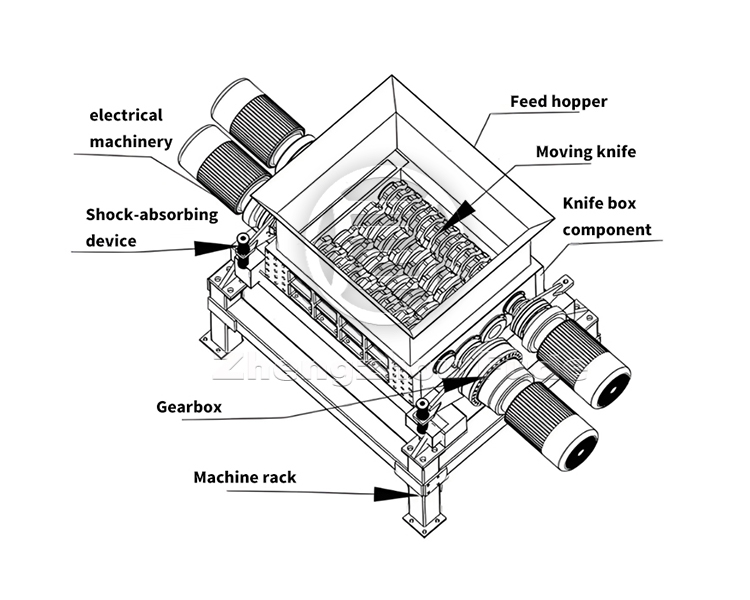

The dual axis shredder mainly consists of knife rollers, screen mesh, fixed cutting tools, loading box, box frame, power supply system, power supply system, and electrical control system.

Large scale scrap iron and steel crusher production line, dual axis crusher, garbage crusher.

The dual axis shredder has low speed and high torque, suitable for cutting harder or larger materials. Such as wood, tires, waste household appliances, metals, etc.

In the era of global resource scarcity and environmental sustainability, the dual-shaft shredder production line has emerged as a cornerstone of modern waste management and recycling.

Designed to handle a wide range of materials—from metals and plastics to rubber and biomass—this system combines robust engineering with advanced automation to deliver unmatched efficiency, durability, and environmental compliance. Below is a comprehensive introduction tailored for international audiences.

How Do You Build a Complete and Efficient Recycling Line?

Yes, the shredder is just the first step. Many businesses think buying a powerful shredder is the end of the story. At Fude Machinery, we show them it is just the beginning. A shredder is the front door to a much larger and more profitable factory. A truly efficient and profitable operation uses a complete recycling line. This is a system where each machine works together perfectly. It’s like an assembly line, but instead of building a product, it takes waste apart and turns it into valuable raw materials. As a manufacturer that has built these lines for over 120 countries, we want to guide you. We will show you how to build a smart, automated system that maximizes your profits and minimizes your costs.

Work video of Double-shaft shredder production line

The dual axis shredder cuts various soft and hard materials into pieces through two sets of cutterheads made of high-grade alloy steel;

This machine is mainly used for crushing and recycling of thick, tough, and large materials (such as large pipe materials and thick wall waste).

The machine adopts a dense row moving blade structure, equipped with hydraulic drive and forced feeding machinery, which has the characteristics of strong crushing ability and high efficiency.

Technical Advantages

- High Throughput & Energy Efficiency

Modern lines process 2,000–35,000 kg/h of material with motor powers ranging from 7.5 kW to 220 kW. Dual-motor drives with hardened gear reducers ensure low-speed, high-torque operation, minimizing energy consumption per ton of processed metal. - Versatility in Material Handling

Beyond metals, these systems efficiently shred plastics, rubber tires, wood, and even electronic waste. Specialized configurations tackle challenging inputs like painted or contaminated scrap, pre-shredding mud-laden materials to protect cutters. - Durability & Low Maintenance

Cutter blades are treated with tungsten carbide coatings or laser cladding to extend lifespan by 3–5 times. Modular designs allow quick replacement of worn components, reducing downtime to less than 2 hours per maintenance cycle.

Large dual axis shredder production line

Wood shredder material crushing principle

The dual-shaft shredder operates by having two parallel-mounted cutting drums rotate at low speeds in opposite directions. The alternating arrangement of moving and stationary blades on the cutting drums creates a combined force of shearing, tearing, and compression.

When material enters the crushing chamber, it is first pulled in by the rotational force of the knife rolls and undergoes initial tearing. It then experiences high-intensity shearing between the sharp edges of the moving and stationary blades, while the gripping action of the knife claws further tears resilient materials (such as rubber and plastic film).

For high-hardness materials (such as metal and wood), the powerful torque of the knife rolls achieves crushing through continuous compression. Throughout the process, the material feeding device ensures stable feeding of large pieces of material and prevents rebound.

The dynamic torque adjustment system automatically adjusts the distance between the knife shafts based on material resistance to prevent overload jamming. Ultimately, the material is crushed into uniform particles ranging from 3 to 30 mm, achieving volume reduction and resource-efficient pre-processing.

Double axis shredder knife roller

Structural diagram of the cutter roller of the dual axis shredder

Good product, please zoom in and take a closer look

Flexible selection of equipment knife rollers based on material characteristics to enhance shredding effect

Shredder blade

coupling

Gearbox

bearing

The purpose of a dual axis crusher

It can generally be used for solid materials such as plastics, rubber, fibers, paper, wood, electrical equipment, cables, etc. that are difficult to crush, such as nozzle materials, rubber heads, polyester bottles, steel cardboard, circuit boards, wood, plastic drums, etc.

Simply put the difficult to break material into a shredder, and the material becomes particles of 20x40mm.The shredder has a low cutting speed during use, ensuring no harm, low noise, low energy consumption, and strong practicality.

Simply put the difficult to break material into a shredder, and the material becomes the desired particle size. The shredder has a low cutting speed during use, ensuring no harm, low noise, low energy consumption, and strong practicality.

Used tires

Waste cardboard box

Waste wood

Scrap iron

Waste plastic bucket

Waste fruit baskets

The crushing effect of waste tires

Crushing effect of waste cardboard boxes

Crushing effect of waste

Scrap iron crushing effect

The crushing effect of the large blue barrel

Fruit basket crushing effect

Basic structure of industrial metal shredders

- Bulk material → shredder → conveyor belt → crusher

- After being crushed by a shredder, the volume of large plastic can generally be reduced by 40%, and some materials can even reach 60%.

- Many plastics in our daily lives can be recycled and reused, such as water pipes, gas pipes, large plastic buckets, and so on. As long as we tear it into small enough particles, we can melt it in an extruder and then extrude it for use.

- But the key point is that the plastic waste particles used for feeding must be small enough, as the process before the extrusion granulation process usually involves crushing the plastic first.

- People’s current lives are no longer separated from plastics, which has led to the generation of large amounts of waste plastics. Recycling waste plastics is a big market. The shredder is an efficient and practical helper for plastic recycling.

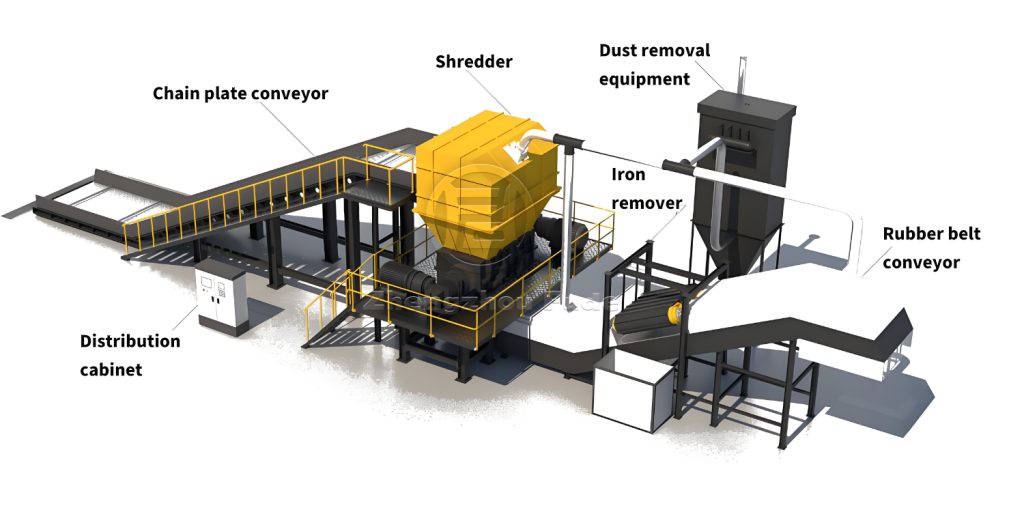

Shredder production line

How to choose the right scrap metal shredder production line for yourself?

Firstly, it is necessary to clarify one’s usage needs; Different industries and production processes have different requirements for shredding.

After clarifying the usage requirements, it is necessary to comprehensively consider the performance, good shredding effect, output, price, and other aspects of different models of shredders to ensure that the selected equipment can meet production requirements. (Factory direct sales, customizable according to customer needs)

Putting It All Together: A Complete Scrap Metal Line Example

So, what does a full system look like? Let’s imagine a complete scrap metal processing line.

- Infeed: A loader drops mixed scrap metal and old cars onto a heavy-duty steel infeed conveyor.

- Primary Shredding: The conveyor feeds the material into a powerful dual-shaft shredder, which tears it into hand-sized pieces.

- Conveying: A conveyor carries the shredded mix up and under a large drum magnet.

- Ferrous Separation: The magnetic separator pulls out all the steel and drops it into a large pile. This is now a clean steel product.

- Non-Ferrous Separation: The remaining material (aluminum, copper, plastic, rubber) continues on another conveyor to an eddy current separator. This machine kicks the aluminum and copper into a separate container.

- Final Product: You now have three separate outputs: a pile of valuable steel, a bin of valuable mixed non-ferrous metals, and a small amount of waste. You have turned a pile of junk into several streams of revenue.

Wood shredder for sale: feedback from the work site

On site display of customers from different regions crushing different materials

Pakistani customer crushing wood on-site

Australian customer crushing scrap on-site

Canadian customer crushing plastic bags on-site

German customer crushing solid waste on-site

scrap metal shredder for sale:Frequently Asked Questions

- Question 1: Do I have to buy the whole complete recycling line at once?

- No. This is a great benefit of working directly with a manufacturer like us. We can design a modular system for you. You can start with a shredder and a simple conveyor. When your business grows, you can add a magnetic separator. Later, you can add an eddy current separator. We help you build your factory in phases.

- Question 2: How much space do I need for a complete recycling line?

- The footprint depends entirely on your needs and throughput. A simple line for plastic might fit in a small warehouse. A high-volume scrap metal line will need a large outdoor yard. We create custom 3D layouts for our clients so you can see exactly how the line will fit on your site before you buy anything.

- Question 3: What is the most important piece of equipment after the shredder?

- For most applications, the most important next step is separation. This is because separation is what creates the most value. Turning a low-value mixed material into several high-value clean materials provides the fastest return on investment.

Delivery and loading of industrial metal shredders

Customized machine loading sites for customers from different countries

Customized machine loading and shipping for Indonesian customers

Customized machine loading and shipping for Russian customers

A shredder is a powerful tool, but it is not a complete business solution. The key to a truly profitable and efficient operation is building a complete recycling line. This system starts with the right shredder. It uses conveyors for automated flow.

It uses separators to unlock the hidden value in your scrap. And it uses screens or grinders to create a perfect final product. Each part works together as a single, smart system.

Stop thinking about buying just a machine. Start thinking about building a factory. As a manufacturer that provides one-stop solutions, we are here to be your partner. We will help you design a complete recycling line from start to finish that is perfect for your material, your space, and your budget. Let’s build a profitable future together.

The dual-shaft shredder production line is not just a machine—it’s a catalyst for sustainable industrial transformation. By converting waste into reusable resources, it bridges the gap between environmental responsibility and economic viability.

Whether you’re a scrapyard operator, recycler, or municipal waste manager, investing in this technology positions you at the forefront of the green revolution.

Contact us today to explore how our shredding solutions can optimize your operations, reduce your carbon footprint, and unlock new revenue streams from waste. Together, let’s build a future where every scrap tells a story of renewal.

Fudemetal Crusher

Fudemetal Crusher