How does a small box type cake press work

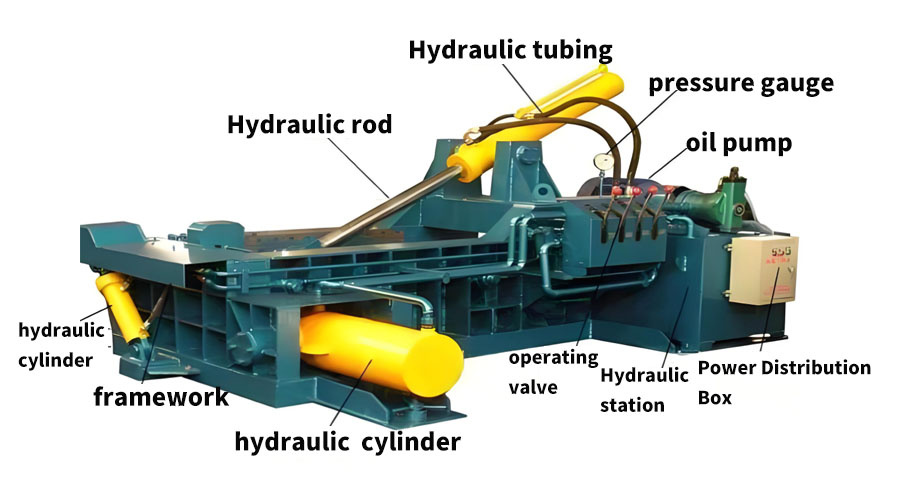

407A small box type cake press is a machine specifically designed for pressing metal waste

View detailsSearch the whole station

Problem: Confused about scrap compression options? Agitate: Choosing the wrong machine wastes money and potential value. Solution: Understand the key difference to pick the right tool.

Choose a Baler for large, bulky scrap like car bodies or sheet metal, aiming for maximum volume reduction to save on transport. Choose a Briquetter for metal chips and turnings to create high-density pucks that increase melting value and recover fluids.

You know compressing metal scrap saves space and money. But the terms “baling” and “briquetting” often get mixed up, leading to costly mistakes. They are fundamentally different processes using different machines for different goals.

As Zhengzhou Fude Machinery, a manufacturer of both types, we want to clarify the distinctions and help you unlock the true potential hidden in your scrap pile by choosing the right technology. Let’s dive deeper than just volume reduction.

Problem: Seeing compression only as a floor space saver? Agitate: You’re missing out on major workflow and safety improvements. Solution: Discover how it optimizes your entire operation.

Compression creates uniform blocks, enabling safe vertical stacking, streamlining internal logistics with fewer forklift trips, reducing handling hazards, and improving overall plant safety and cleanliness significantly.

Yes, squashing scrap reduces its footprint. But the benefits go far beyond simply clearing floor space. Think about how standardized blocks transform your workflow and environment.

Loose scrap is bulky and unstable. You can’t stack it high. Compressed bales or briquettes, however, are dense and uniform.

Moving loose scrap is inefficient and messy. Compressed blocks change that.

Loose scrap, especially sharp turnings, poses risks. Compression mitigates these.

Problem: Facing high bills for hauling away scrap? Agitate: You might be paying to transport mostly air inside the truck. Solution: Maximize the weight per load through high-density compression.

The secret is loading trucks closer to their maximum weight limit, not just filling their volume. High-density bales or briquettes achieve this, drastically cutting the number of trips needed and the transport cost per ton.

Reducing the number of transport trips is a major goal of scrap compression. But the effectiveness hinges on one crucial factor: density. You need to think about truck capacity in terms of weight, not just space.

A standard truck trailer has both a volume limit and a weight limit (payload capacity).

Calculating the Savings

By maximizing the payload weight per trip, you dramatically reduce the total number of trips required.

Problem: Treating valuable metal chips as low-grade waste? Agitate: Significant profit is lost through melt burn-off and discarded fluids. Solution: Briquetting boosts intrinsic value through higher yield and fluid recovery.

Briquetters create high-density pucks that minimize metal loss during melting, boosting yield significantly. They also squeeze out valuable cutting fluids for reuse, adding another direct revenue stream or cost saving.

While balers primarily save money on handling and transport, briquetters directly increase the intrinsic value of metal chips and turnings in several ways. This is especially true for machine shops and foundries.

This is often the biggest financial gain.

This is a unique benefit of high-pressure briquetting.

Command Purity Premiums

Clean, source-separated scrap is always more valuable.

So, When Do I Absolutely Need a Baler vs. a Briquetter?

Problem: Still feeling uncertain about which machine truly fits your needs? Agitate: Investing in the wrong technology leads to inefficiency and regret. Solution: Clearly match the machine to your specific scrap type and primary objective.

Get a Baler if you handle large, bulky scrap (vehicles, appliances, sheet offcuts) and your main goal is reducing volume for easier handling and cheaper transport. Get a Briquetter for fine chips, turnings, or powders to maximize melting value and recover cutting fluids.

The choice between a baler and a briquetter comes down to two simple questions: What kind of scrap do you have? And what is your primary goal? Let’s clearly define the roles.

Mixing these up is a fundamental error. Trying to bale fine chips won’t achieve the density needed for good melting results. Trying to stuff a car body into a briquetter is impossible. Purpose dictates the technology.

Problem: Getting focused only on the advertised tonnage rating? Agitate: Ignoring machine suitability, reliability, and support leads to long-term headaches. Solution: Prioritize real-world testing, density achievement, automation needs, and robust construction.

Look past simple tonnage. Test the machine with your scrap. Focus on achieving the required final density (psi/kg/cm² matters). Evaluate automation ROI. Critically assess structural integrity, hydraulic quality, wear parts, cooling, and supplier support for long-term success.

Selecting the right baler or briquetter involves more than just comparing basic specifications like motor power or main cylinder force (tonnage). Here’s what experienced operators and we, as manufacturers, focus on:

1. Material Characteristics First

2. Density is King (Especially for Briquetters)

3. Capacity and Automation Needs

4. Reliability and Maintenance (The Long Game)

Investing wisely means looking at the total cost of ownership, not just the purchase price.

Choosing correctly between a baler and briquetter, based on your scrap and goals, unlocks significant operational and financial benefits far beyond just saving space. Understand the differences, focus on real-world performance, and invest wisely.

Fude Machinery has always been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, it has received satisfactory praise from customers.

A small box type cake press is a machine specifically designed for pressing metal waste

View detailsThe metal shredder achieves the crushing of metal materials through the coordinated work of the power system, tool system, deceleration system, and feeding system.

View detailsPlastic crushers play an important role in the field of plastic recycling and reuse,

View detailsHorizontal baler is a compression and packaging equipment mainly used for various loose materials such as waste paper, cardboard boxes, straw, etc.

View details