In the global context of rapid industrialization and urbanization, waste foam materials—including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane (PU)—have become ubiquitous in packaging, construction, and daily life. However, their non-biodegradable nature poses significant environmental challenges.

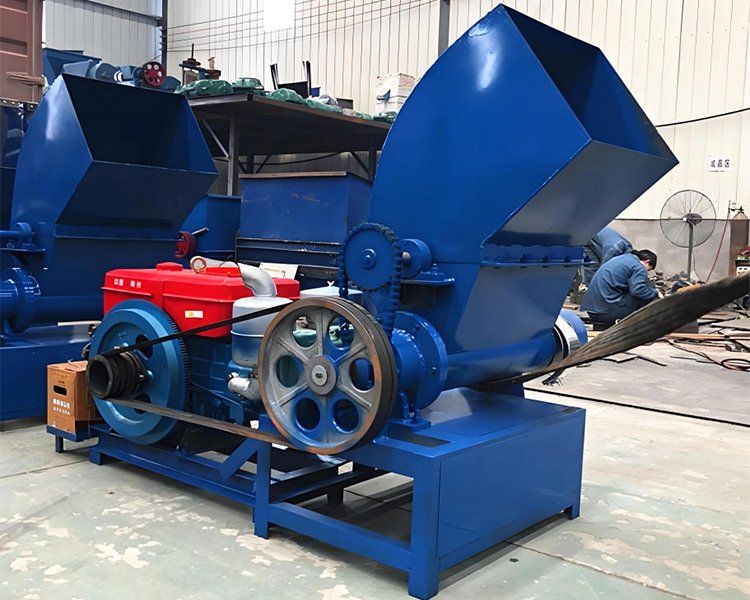

The Foam Block Molding Machine (also known as foam compactor or foam melting machine) emerges as a revolutionary technology, transforming waste foam into reusable, high-density blocks for efficient recycling and resource regeneration.

The working principle of the foam melting machine

The working process of a foam block machine is a precision system that integrates mechanical, thermal, and pressure control. It mainly consists of three core steps: crushing, heating and melting, and extrusion molding.

- Crushing stage: Waste foam, such as common polystyrene (EPS) foam, is first fed into the machine’s feed port. High-speed rotating blades inside the machine quickly cut large pieces of foam into small fragments. This process not only increases the surface area of the foam, facilitating subsequent heating and melting, but also effectively prevents large pieces of foam from clogging the machine, ensuring stable operation of the equipment.

- Heating and melting stage: The crushed foam fragments are transported to the heating chamber. The heating chamber uses advanced heating technology, such as electric heating or gas heating, to precisely control the temperature. At the appropriate temperature, the foam fragments gradually soften and melt, forming a liquid foam with a certain degree of fluidity. During this process, the machine continuously stirs to ensure that the foam is heated evenly and to prevent local overheating or unmelted areas.

- Extrusion molding stage: The melted liquid foam is pushed into the molding mold by the extrusion device. Under high pressure, the liquid foam is compressed into high-density blocks or strips. After cooling and solidification, these molded products can be easily stored, transported, and reprocessed.

Performance characteristics of foam hot melt machines

- High-efficiency processing capacity

Foam shredders have powerful processing capabilities and can quickly process large amounts of waste foam. Depending on the model and specifications, their processing capacity ranges from tens of kilograms to several tons per hour. Whether it is a small recycling station or a large industrial production enterprise, there is a suitable equipment model for every production need, greatly improving the efficiency of foam recycling.

- Energy-saving and environmentally friendly design

With energy becoming increasingly scarce today, energy conservation has become an important consideration in equipment design. The foam block machine adopts advanced energy-saving technologies, such as an intelligent temperature control system that can automatically adjust the heating power according to the melting status of the foam, thereby avoiding energy waste. At the same time, the machine generates less noise and dust during operation, has a minimal impact on the environment, and meets environmental protection requirements.

The device has a simple and clear user interface, and operators can start using it after just a bit of training. It’s got all the safety features you need, like overload protection and leakage protection, to keep accidents from happening and keep operators safe.

The foam block machine produces stable and reliable foam blocks. The density of the molded blocks or strips is uniform, making them easy to reprocess and reuse. Whether used to manufacture new foam products or as fuel or other industrial raw materials, they can meet the needs of different industries.

Applications of Foam Compaction Machines

The foam block machine uses mechanical compression and thermal melting technology to compress waste foam plastic into high-density blocks. Its applications span three core industries: environmental protection, manufacturing, and logistics.

In the environmental protection sector, this equipment serves as a core processing tool for waste recycling stations and professional recycling companies, efficiently handling waste materials such as expanded polystyrene (EPS) and polyurethane insulation boards. A single unit can process hundreds of kilograms to several tons per day, significantly reducing environmental pollution caused by landfilling or incineration while boosting resource recycling rates by 30%-50%.

In the manufacturing sector, the equipment directly addresses the scrap material processing needs of foam product manufacturers, such as packaging foam for home appliances and waste materials from building insulation boards. By melting and re-granulating in real-time, it reduces raw material waste while lowering the company’s solid waste disposal costs.

In the logistics industry, the portable machine models enable on-site processing of transportation packaging materials, such as e-commerce delivery foam boxes and cold chain insulation materials. After compression, the volume of the resulting blocks is reduced to 1/50 of their original form, significantly optimizing warehouse space utilization and reducing carbon emissions from long-distance transportation.

Additionally, the equipment’s intelligent control system supports precise adjustment of temperature and pressure parameters, enabling it to adapt to the processing needs of different foam materials. This further expands its application potential in niche markets such as automotive interior foam and medical device packaging.

Advantages of Foam Hot Melt Machines

The foam hot-melt machine, equipped with an advanced heating system and precise temperature control technology, can efficiently melt solid foam raw materials into a uniform melt in a short time, significantly improving production efficiency.

Its unique insulation design significantly reduces heat loss, and combined with an electric-to-thermal heating method, it achieves energy savings of over 30% compared to traditional equipment. Additionally, the production process generates no wastewater or exhaust emissions, meeting environmental standards.

The equipment integrates crushing, compression, and transmission functions into one unit, supporting automated continuous operation and reducing manual intervention. Its modular structure facilitates maintenance and can flexibly adapt to processing needs across multiple industries, including automotive interiors, building insulation, and packaging materials. It is a powerful tool for plastic processing that balances efficiency, energy savings, and environmental protection.

Case Study: China’s Innovation Leadership

China dominates the global foam recycling equipment market, with manufacturers like Fude Machinery pioneering cost-effective solutions. Their YZ-300 model features:

- Automatic temperature control for consistent block quality.

- Dual-power options (electric/diesel) for rural areas.

- 1-year warranty + lifetime technical support, reducing buyer risk.

These machines have been exported to 30+ countries, including Brazil, Nigeria, and Malaysia, where they support local waste management policies and create green jobs.

The Foam Block Molding Machine represents a critical tool in the global fight against plastic pollution. By converting waste foam into valuable resources, it bridges environmental sustainability with economic viability. For businesses seeking to capitalize on this trend, investing in reliable, technologically advanced equipment is the first step toward a greener future.

Fudemetal Crusher

Fudemetal Crusher