What is a metal chip press

701The metal chip press is an efficient, environmentally friendly, and energy-saving equipment for processing metal waste

View detailsSearch the whole station

Choosing between a plastic shredder and a plastic crusher is a critical decision for your recycling business. They both reduce the size of plastic, but they do it in very different ways and for different purposes. Choosing the wrong one can lead to inefficiency and high costs. We are Fude Machinery, a dedicated manufacturer of this equipment. We will help you understand the difference so you can make the right choice.

The main difference is that a shredder tears material with high torque, while a crusher cuts material with high speed. Think of it like this: a shredder is like a butcher’s cleaver, designed for breaking down large, tough items. A crusher, or granulator, is like a chef’s knife, designed for quickly dicing smaller pieces into a fine, uniform size.

We build both machines because they solve different problems. A plastic shredder machine is for primary size reduction. It takes large, bulky items like car bumpers or plastic drums and breaks them into smaller, rough chunks. A plastic crusher machine is for secondary grinding. It takes those smaller chunks and quickly reduces them to small, consistent flakes, ready for the next step.

Here is a simple breakdown of their core differences.

| Feature | Plastic Shredder | Plastic Crusher (Granulator) | What This Means for Your Business |

|---|---|---|---|

| Primary Job | Primary size reduction (Bulk to Chunks) | Secondary size reduction (Chunks to Granules) | Use a shredder for your first step with large items. |

| Speed | Low Speed (slow rotation) | High Speed (fast rotation) | Crushers have much higher throughput for smaller items. |

| Power Type | High Torque (strong twisting force) | High Impact (fast cutting force) | Shredders can handle very tough and mixed materials. |

| Input Material | Large, bulky, heavy, contaminated items | Smaller, uniform, pre-shredded pieces | Do not feed large, heavy items directly into a crusher. |

| Output Size | Larger, less uniform pieces (20-100mm) | Small, uniform granules (<15mm) | A crusher gives you a finished, consistent product size. |

| Blade Type | Thick, robust hooks or blocks | Sharp, angled knives (Claw, Flat, V-type) | Crusher blades are for cutting, not for brute force. |

You should choose a plastic shredder when you are dealing with large, bulky, heavy, or contaminated materials. A shredder is a powerful, high-torque machine that can handle difficult waste streams that would instantly destroy a crusher. It is the tough “front line” machine in a serious recycling operation.

We recommend a heavy duty plastic shredder for professional recycling plants that receive unsorted or difficult waste. This includes materials mixed with dirt, some metal, or other contaminants. The shredder’s slow speed and powerful tearing action can handle these challenges. For example, it can process entire bales of plastic film or large, webbed plastic parts without a problem.

Choose a Shredder for These Materials:

We offer both single-shaft and double-shaft industrial plastic shredders to handle these diverse needs. Double-shaft models are excellent for pure volume reduction, while single-shaft models can give you a more consistent output size.

You should choose a plastic crusher, also called a granulator, when you need to create small, uniform granules at high speed. A crusher is the right tool for the job when your input material is already relatively small and clean. It is a high-speed machine designed for efficiency and a consistent final product.

We often see crushers used in two main scenarios. First, by plastic product manufacturers who want to recycle their own clean factory scrap, like runners from injection molding. Second, they are used as a secondary machine in a larger recycling line, right after a shredder. The crusher takes the rough chunks from the shredder and quickly turns them into valuable, uniformly-sized flakes. Feeding a crusher the right material is key to its long life and performance.

Choose a Crusher for These Applications:

The choice of blade—Claw, Flat, or V-type—is critical. For example, a V-type blade is perfect for bottles, while a Claw-type blade is better for harder, thicker scrap. We can help you select the perfect configuration.

For most high-volume, professional plastic recycling operations, the answer is yes. You need both. Using a two-stage system with both a shredder and a crusher is the most efficient, effective, and economical way to operate. This combination gives you the best of both worlds.

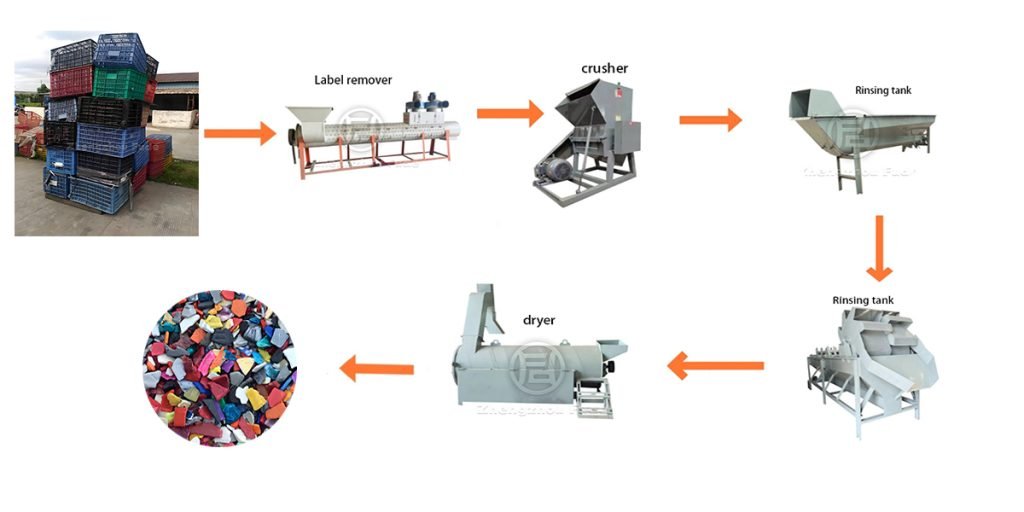

We design many complete plastic washing and recycling lines for our B2B clients, and this two-stage approach is the industry standard for a reason. The shredder acts as a protective first stage. It takes the big, dirty, and difficult waste and turns it into a manageable size. The crusher then takes this pre-processed material and efficiently turns it into a high-quality, valuable final product.

Benefits of a Two-Stage System:

As a factory-direct manufacturer, we don’t just sell machines; we build complete solutions. We understand that your business is unique. Your materials, your facility layout, and your production goals are different from anyone else’s. That’s why buying “off-the-shelf” is often a mistake.

Our entire process at Fude Machinery is designed around providing customized shredder solutions. We start by listening to you. What are you processing? What is your target output in kilograms per hour? What is the final size you need? Based on your answers, our engineers will design a system—whether it’s a single machine or a full line—that is perfectly matched to your needs and budget. This factory-direct partnership saves you money by eliminating middlemen and ensures you get equipment that works for you from day one.

1. Can a plastic crusher handle large items like a drum?

No, you should not feed a large plastic drum directly into a crusher. The high-speed rotor is not designed for such a large, bulky item. This will likely cause a major jam or severely damage the machine. This is a job for a shredder.

2. What is the typical output size from a shredder vs a crusher?

A shredder typically produces rough chunks ranging from 20mm to 100mm. A crusher produces much smaller, more uniform granules, usually 15mm or less. The final size from a crusher is controlled by the size of the holes in its output screen.

3. Is a shredder more expensive than a crusher?

Generally, yes. Shredders are larger, heavier machines with more powerful motors and gearboxes designed for high torque. They are a bigger investment upfront. However, using them correctly protects your less expensive crusher and makes your whole line more profitable.

4. Can I just use one powerful crusher for everything?

While some very powerful granulators exist, it is not an efficient approach. You will spend far more on energy and blade maintenance than you would with a proper two-stage system. Using the right tool for the job is always more cost-effective in the long run.

The choice between a plastic shredder and a plastic crusher is simple when you know their roles. A shredder is for primary, heavy-duty breaking of large and tough materials. A crusher is for secondary, high-speed grinding of smaller items into uniform granules. For most professional recyclers, a two-stage system using both is the most efficient and profitable solution.

The most important step is to partner with a manufacturer who understands your specific needs. As a factory-direct producer, we can provide expert guidance and build the exact equipment you require, saving you time and money.

Ready to find the right machine for your plastic waste?

Let our experts help you. Tell us about the materials you need to process and your production goals. We will provide a free technical recommendation and a competitive, factory-direct quote to build the perfect solution for you.

Contact Fude Machinery today to start the conversation!

The metal chip press is an efficient, environmentally friendly, and energy-saving equipment for processing metal waste

View detailsCrocodile shearing machine is a type of metal shearing machine, mainly used for cold cutting of various shapes of steel and metal structures.

View detailsWhy is "Recipe" a Better Word Than "Shredding"?Which "Recipe Step" is Right For Your Wood?FAQ: Your Wood Shredder Business QuestionsConclusion: Start Cooking Up a More Profitable ProductAbout Fude Machinery Every year, businesses handle millions o...

View detailsPlastic crusher is an important equipment in the field of plastic recycling and reuse.

View details