What is the working principle of a metal compactor

752Metal briquetting machines have a wide range of applications in fields such as metal processing and scrap metal recycling

View detailsSearch the whole station

Metal shredders are essential machines in the recycling and waste management industries. They are designed to reduce large pieces of metal into smaller, more manageable sizes, facilitating easier handling, transportation, and further processing.

A metal shredder, also known as a scrap metal shredder, is a machine used to reduce the size of various metal materials. These machines come in different configurations and sizes, tailored to handle specific types of metal waste. The primary function is to process scrap metal into smaller pieces for recycling purposes.

Single Shaft Shredders

Single shaft shredders are equipped with a single rotating shaft fitted with blades. They are ideal for processing materials like plastic, wood, and light metals. Key features include:

Twin Shaft Shredders

Twin shaft shredders feature two interlocking shafts that rotate in opposite directions. They are suitable for heavy-duty applications, including metal recycling and industrial waste processing. Advantages include:

Four Shaft Shredders

Four shaft shredders incorporate two primary shafts and two secondary shafts, providing finer shredding and increased output. They are used for complex materials requiring precise size reduction.

Metal shredders are utilized in various industries for processing:

Fudemetalcrusher Shredder Features

OverviewProduct SpecificationsName: Metal CrusherModels & CapacitiesKey FeaturesBenefitsWhy Choose Fudemetalcrusher?Contact Us Introducing the Fudemetalcrusher Solid Waste Shredder, the ultimate solution for scrap metal recycling and processing. Engineered with advanced technology and robust construction, our shredders are designed to hand…

Multifunctional Single Shaft ShredderWorking video of a single axis shredderWhat is a scrap metal shredderMetal recycling shredder Product featuresThe working principle of industrial rubber shredderIndustrial rubber shredder is widely usedScrap metal shredder suppliers:Customer Feedbacksmall scrap metal shredder for sale:Customer shipment site…

Working video of a single axis shredderWhat is a single axis crusher?Product advantagesThe working principle of a single axis shredderWide application range, visible tearing effectCustomer shredding sites in different regionsCustomer shipment siteHow to choose a single axis shredder? Multi functional and practical single axis wood shredder …

A single-shaft shredder for multifunctional useWorking video of a Single shaft shredderWhat is a single axis crusher?Product characteristics of metal shredderThe working principle of a Metal ShredderIndustrial rubber shredder is widely usedCustomer shredder sites in different areasScrap metal shredder suppliersHow to choose a shredder heavy meta…

Fudemetalcrusher offers advanced shredding solutions with features such as:

Summary Table

| Shredder Type | Key Features | Applications |

|---|---|---|

| Single Shaft | Efficient, precise, low energy consumption | Plastics, wood, light metals |

| Twin Shaft | High torque, handles bulky materials | Heavy-duty metal recycling, industrial waste |

| Four Shaft | Finer shredding, increased output | Complex materials requiring precise reduction |

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

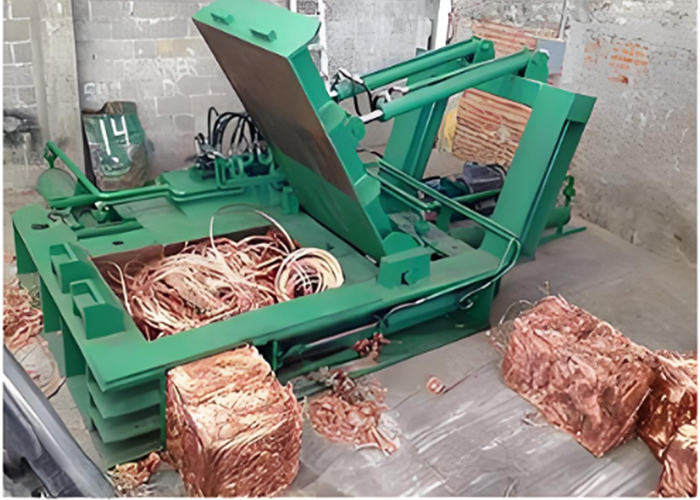

Metal briquetting machines have a wide range of applications in fields such as metal processing and scrap metal recycling

View detailsIn this guide, we'll walk you through the top 10 heavy-duty shredders of 2024, explore their features, applications, and help you make an informed decision.

View detailsLongmen shearing machine, also known as CNC shearing machine, is a precision metal cutting equipment widely used in the field of metal processing.

View detailsThere are two types of machines, metal chip compactor and metal packaging machine, which directly cold press various waste into shape through high pressure, making it easy to store, transport, and recycle.

View details