What is a metal crusher

485Metal crusher is an efficient, energy-saving, and environmentally friendly waste metal processing equipment

View detailsSearch the whole station

Problem: Choosing the wrong industrial shredder wastes your time and money. Agitation: It leads to poor results and equipment damage. Solution: Learn how to pick the perfect shredder.

The best industrial shredder depends entirely on your specific situation. Key factors include the type of material you process, the final particle size you need, and the volume you handle daily. Matching the shredder to these needs ensures efficiency.

Choosing a shredder isn’t a one-size-fits-all task. Different machines excel at different jobs. We need to look closely at what you plan to shred and what results you expect. Let’s explore the details to help you make the right choice for your business.

Problem: Thinking any shredder can handle any material causes issues. Agitation: This leads to breakdowns and inefficient shredding. Solution: Understand that material properties are key.

Materials differ greatly in hardness, shape, density, and how they react to cutting. Shredders are designed with specific cutting systems and power levels to work best with certain material characteristics. Using the right match prevents damage and maximizes output.

Materials behave differently when you try to break them down. Understanding these differences is the first step in selecting the right machine. We, at Zhengzhou Fude Machinery, have seen how material properties drastically affect shredder performance based on our experience since 2015.

Material Hardness

Hard materials like scrap metal need robust shredders with high torque and strong cutters. Softer materials like plastic film or cardboard require different cutting actions to avoid wrapping or jamming. A shredder built for metal might tear plastic inefficiently, while a plastic shredder would be destroyed by metal.

Material Elasticity

Some materials, like rubber tires, are elastic. They bounce back and absorb impact. Shredders for tires need sharp, shearing cutters and enough power to overcome this elasticity. Trying to shred tires with a machine designed for brittle materials will be slow and ineffective.

Material Bulkiness and Form

The physical form matters too. Bulky items like furniture or large plastic containers need shredders with wide openings and strong feeding mechanisms. Materials like municipal solid waste (MSW) are very mixed, containing everything from food scraps to plastics and metals. This requires versatile shredders, often double-shaft designs, that can handle variety without constant sorting.

Problem: You have specific waste like metal or tires but are unsure which shredder type is suitable. Agitation: Buying the wrong type is a costly mistake. Solution: Know the common pairings.

Single-shaft shredders work well for controlled size reduction of plastics and wood. Double-shaft shredders excel with bulky, tough items like tires, MSW, and light metals. Four-shaft shredders offer more precise sizing, often used for complex scrap or secure destruction.

Matching the shredder type to your primary material stream is crucial for efficient operation. Let’s look at common materials and the shredder types generally recommended for them. As a manufacturer, we provide single-shaft, double-shaft, and four-shaft options to cover these diverse needs.

Metals

Scrap metal, especially denser items, usually requires double-shaft shredders. Their high torque and robust shearing action can handle tough materials. For lighter gauge metals or applications needing smaller, more uniform output, a heavy-duty single-shaft or even a four-shaft shredder might be considered. We design metal shredding lines specific to input type and desired output.

Plastics

Plastics come in many forms. Rigid plastics (crates, pipes) and purgings are often processed with single-shaft shredders for good size control using screens. Film and flexible plastics can wrap around shafts, so specialized rotor and cutter designs are needed, sometimes found in single-shaft models designed for film. Double-shaft shredders can handle mixed or bulk plastic waste effectively.

Wood

Wood waste like pallets, demolition wood, and forestry residue is commonly shredded using single-shaft shredders for consistent chip size, ideal for fuel or particleboard. Double-shaft shredders can handle bulkier wood waste or wood contaminated with nails and bolts.

Tires

Tires require high-torque double-shaft shredders due to their elasticity and steel belts. These machines shear the tires into rough strips. Further processing often involves secondary shredders and granulators to achieve smaller rubber crumb sizes. We build complete tire recycling lines.

Municipal Solid Waste (MSW)

MSW is highly varied. Double-shaft shredders are the workhorses here, capable of handling bulky items and diverse materials found in household or commercial waste streams. They provide volume reduction before landfilling or further sorting/processing.

Problem: The terms single, double, four-shaft are confusing. Agitation: Choosing the wrong configuration means poor performance or unnecessary cost. Solution: Understand their basic mechanics and strengths.

Single-shaft shredders use one rotor with cutters pushing material against stationary knives, often with a screen for size control. Double-shafts use two counter-rotating shafts with interlocking cutters for powerful shearing. Four-shafts use two primary shafts plus two secondary shafts for combined shredding and sizing.

The number of shafts directly relates to how the shredder cuts material and what it’s best suited for. Each design has advantages depending on the application. At Fude Machinery, we manufacture all three types, allowing us to recommend the best fit.

Single-Shaft Mechanism

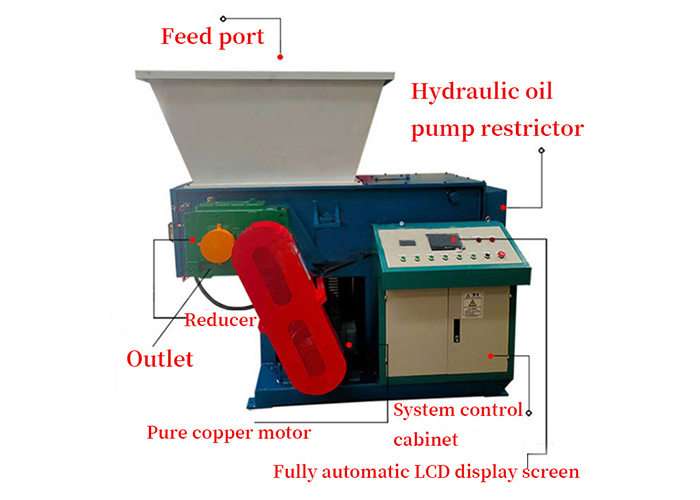

A single rotor spins, equipped with cutter blocks. Material is fed into the chamber, and a hydraulic pusher (ram) forces it against the rotating cutters. Material is cut between the rotor cutters and fixed stator knives. A screen underneath the rotor determines the final particle size – material stays in the chamber until small enough to pass through the screen holes.

Double-Shaft Mechanism

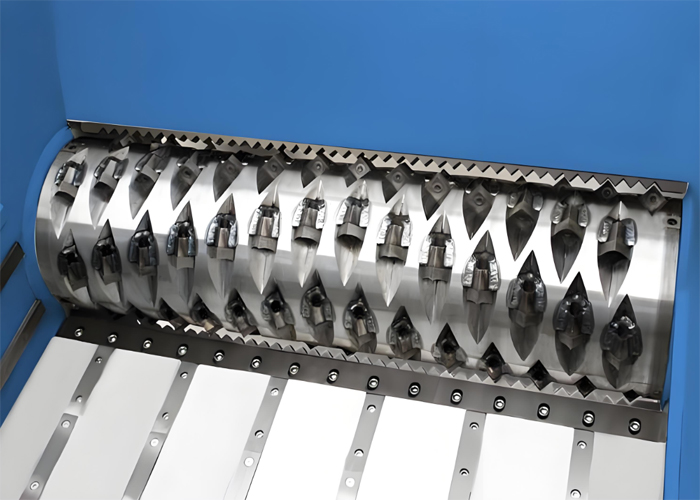

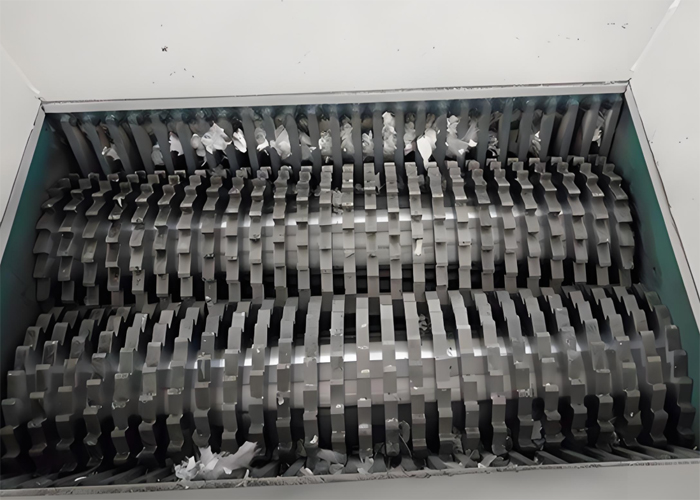

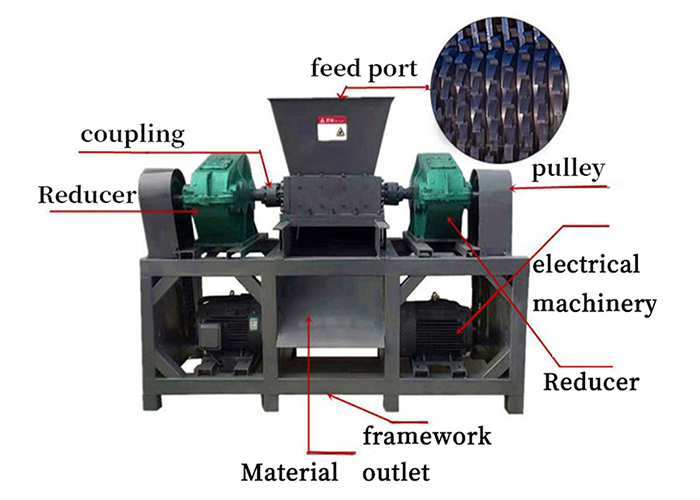

Two parallel shafts with hooked cutters rotate towards each other at relatively low speed but high torque. Material is pulled into the gap between the shafts and sheared/torn by the interlocking cutters. There is no screen, so output size is less uniform, determined mainly by cutter width.

Four-Shaft Mechanism

This design typically uses two primary shafts similar to a double-shaft shredder for initial breakdown. Below these, two secondary shafts, often with different cutter designs, work with a screen to provide further size reduction and ensure a more consistent final particle size.

The size of crushed material is often critical. It may need to meet buyer specifications, suit subsequent processing equipment, or achieve maximum compression efficiency. These requirements directly influence which type of crusher is most suitable.

Note: Ranges are broad and highly dependent on the specific model and application.

Problem: You’ve focused only on the shredder type (single/double/four-shaft). Agitation: Ignoring other specifications can lead to poor performance, high costs, or safety issues. Solution: Pay attention to these core parameters too.

Beyond type, evaluate motor power, cutter material and design, chamber dimensions, safety features, control system intelligence, and ease of maintenance. These factors directly impact the shredder’s performance, durability, running costs, and operator safety.

Choosing the right type is just the start. The detailed specifications determine if a shredder will truly meet your needs reliably and cost-effectively. As manufacturers, we focus on these details to ensure quality and performance.

| Parameter | Importance | What to Look For |

|---|---|---|

| Motor Power | Performance, Throughput | Sufficient kW/HP for application, Quality Drive System |

| Cutter Material/Design | Durability, Cutting Efficiency, Operating Cost | Hardened Alloy Steel, Replaceable/Rotatable, Suited Shape |

| Chamber Dimensions | Material Handling Capability | Matches Input Size and Feed Method |

| Safety Features | Operator Protection, Compliance | E-stops, Overload Protection, Guarding, Standards |

| Maintenance Access | Reduced Downtime, Longevity | Easy access to cutters, screen, lubrication points |

| Control System | Efficiency, Protection, Diagnostics | Smart Overload response, Auto-reverse, User-friendly |

Problem: You want to contact suppliers like us for quotes or advice. Agitation: Providing vague information leads to inaccurate recommendations or wasted time. Solution: Prepare detailed information about your needs beforehand.

The more detailed information you provide us, the better we can help you select the optimal shredder or design a complete system. Clear communication prevents misunderstandings and ensures the proposed solution truly meets your operational goals. As a manufacturer specializing in customization, this input is vital.

| Information Provided | Why It’s Important for the Supplier |

|---|---|

| Detailed Material Specs | Selects correct shredder type, cutters, power |

| Desired Output Size | Determines need for screen, cutter width, shredder type |

| Required Throughput | Sizes the machine correctly (motor, chamber) |

| Budget Range | Narrows down feasible models and options |

| Site Limitations (Space/Power) | Ensures the proposed machine fits and can run |

| Contamination Levels | Affects shredder robustness, potential pre-sorting needs |

| Future Plans | Allows planning for scalability or flexibility |

Providing this information allows us at Zhengzhou Fude Machinery to leverage our experience and offer you the most effective and economical shredding solution, tailored to your unique B2B needs.

Choosing the right industrial shredder involves matching the machine to your specific material, desired output size, required volume, budget, and site conditions. Understanding these factors is key.

Zhengzhou Fude Machinery Equipment Co., Ltd. is a professional enterprise engaged in the research and development, production, and sales of metal processing equipment. We are committed to providing customers with efficient, stable, and reliable pre-sales and after-sales services.

The company always adheres to the concept of “technological innovation, quality first”, continuously improves its technical strength and service level, provides customers with high-quality metal crushing solutions, and creates greater value for customers.

Metal crusher is an efficient, energy-saving, and environmentally friendly waste metal processing equipment

View detailsCan I Use a Metal Baler for Machine Shop Chips and Turnings?Are Metal Balers Effective for Sheet Metal Offcuts and Stampings?Can Metal Balers Handle Scrap Wire and Cable Effectively?Will a Metal Baler Work for Heavy Castings or Structural Steel?Ho...

View detailsTable of ContentsIntroductionWhat Is a Metal Crusher?How a Metal Crusher Works1. Feeding the Materials2. Crushing Mechanism3. Output and RecyclingTypes of Metal Crushers1. Single-Axis Crushers2. Dual-Axis Crushers3. Waste Treatment CrushersBenefi...

View detailsThe main purpose of the waste paper horizontal baler is to effectively compress and pack waste paper and similar products

View details